Liming Stamping Form Machine Co., Ltd. was established in 1995.

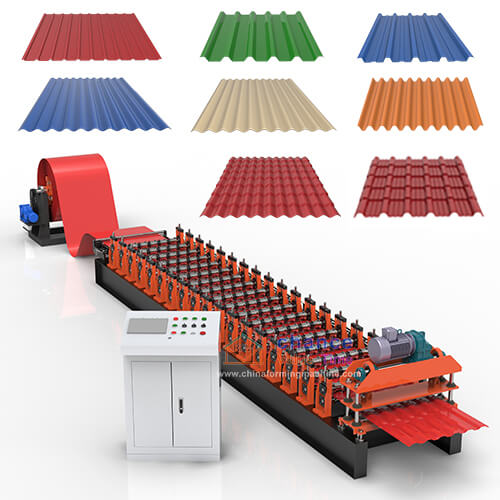

Roof Panel Machine

Roof Panel Machine

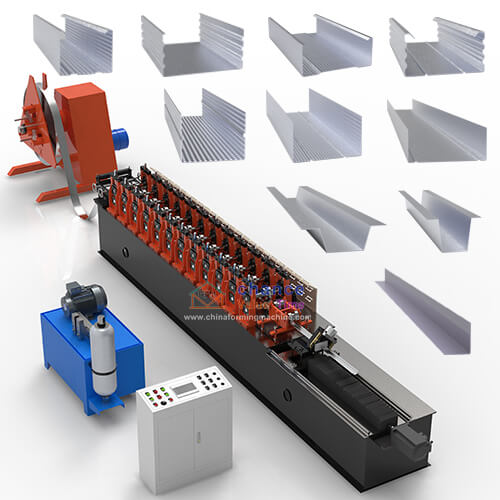

Drywall Machine

Drywall Machine

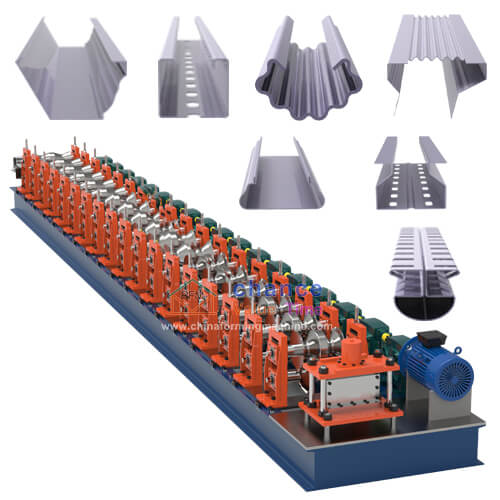

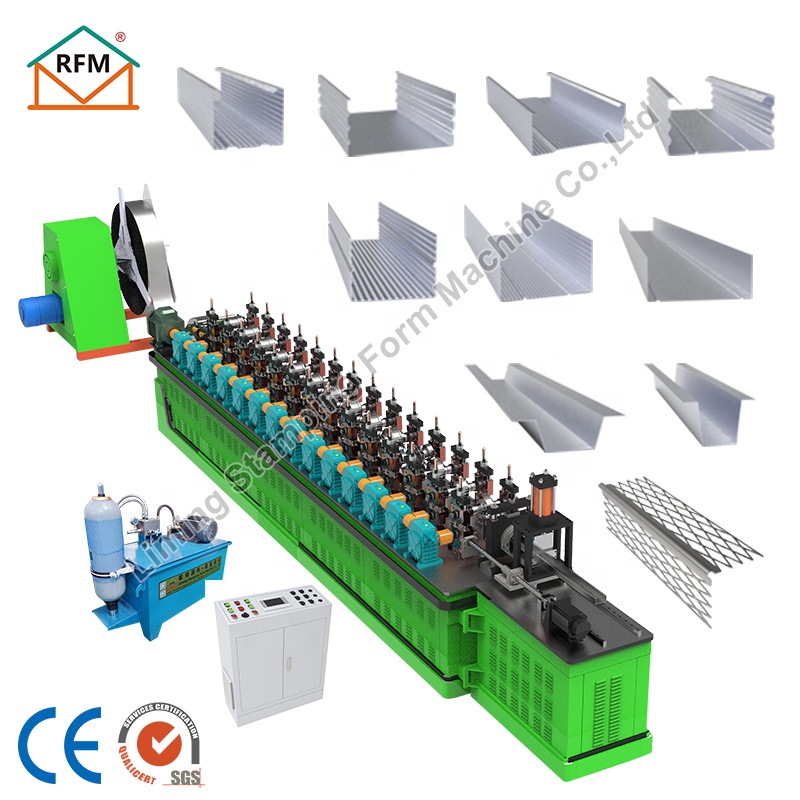

Customized Profiles

Customized Profiles

Through our newsletter and live playback, you can understand and analyze related topics well.

We look forward to welcoming you as a new subscriber to our newsletter and live playback. You can cancel your registration at any time.

All kinds of Cold roll forming machine:Glazed Roof Tile Roll Forming Machine,High-speed Steel Frame Roll Forming Machine.

Liming is an overseas supplier of roll forming machine solutions for your industry; We have the most comprehensive configuration of roll forming machine supporting production line to meet customer needs and different budgets, all roll forming machine upgrade configuration can be purchased at cost price.

LIMING's newly developed stud and track roll forming machine can meet the production needs of customers in two product models, production speed 120m/min, man-machine operation screen one-button adjustment product size width, is a trusted manufacturer for customers in the building decoration industry.

The leader in door industry roll forming machine, we provide rolling shutter door forming machine, door frame forming machine, door panel production line, fully automatic integrated door leaf production line; provide the most comprehensive service for door industry manufacturers

Copyright © 2020-2023 Roll Forming Machine All Rights Reserved.