Cable tray and its application

Bare wires are most dangerous when they are exposed. Bare wires can damage your workplace and even your life. Wires and cables in almost all industries are a mess, and finding a reliable solution to manage them is the most difficult task, especially when they have a high level of security. A cable tray is a bridge that can safely transport wires across open distances and provides protection against overheating and fire buildup problems. It is a cable management system with various sizes and styles that can simplify the work of entering or exiting new or existing wires in the tray. These are used to handle heavy wire bundles and protect them from any damage. There are several types of cable trays on the market, including ladders, galvanized, perforated, PVC, stainless steel, etc. Before choosing any of them, pay close attention to its configuration to take you in the right direction.

Cable trays are the preferred solution for wiring and supporting numerous cable routings. This applies to desks, raised floors or under suspended bridge systems. One person can assemble basket pallets for intersections, horizontal sections, mounting brackets, hardware and pallet cutters.

The cable tray made of welded steel wire is considered the most popular copper cable and data cable support. The basket is light and easy to install, and is equipped with a complete set of cable tray accessories. It is recommended to use a solid basket tray for heavier wires. These baskets are manufactured to withstand natural factors. Although the material is not solid steel, it protects the cable from corrosion and has a longer service life.

Cable trays have always been a popular choice for effectively supporting and routing cables in commercial environments, and quick installation is still the most important factor affecting the performance enhancement of cable trays.

The physical structure of the building will tell you the span and type of support required, while the environment will tell you the type of finish required. For example, aluminum has better corrosion resistance in outdoor applications.

Popular cable tray styles include double-sided, middle rail and wire mesh basket tray systems:

●The most common double-sided ladder frame in exposed areas (such as data centers) is similar to a ladder with sturdy parts for fixing cable bundles

●The middle rail cable tray facing the communication cable is suspended in the center, and there are open steps on both sides, so that the cable can be installed easily. The center rail provides maximum convenience and flexibility for the installation and removal of cables, which is an ideal choice for data communication applications with many moving, adding and changing functions. The tray can be simply filled or emptied on the side, and multiple cables can be easily placed in any position as needed

●Wire basket cable tray is a kind of lightweight, usually double-sided wire basket, which can be suspended by aerial trapezoid, center or wall bracket.

The cable tray system can provide prefabricated joints, and has a variety of protective powder coating color topcoats, which can meet the needs of customers who want to color-code the path

Wire and cable trays and wire basket cable trays provide twice the cable support area to better support data communications and optical fiber wiring, and save time and money in those light-weight cable support projects. Work site, on-site applicable support system, mainly used for low voltage, telecommunications and optical cables. The wire mesh cable tray is made of galvanized, galvanized, painted and stainless steel wire mesh. Wire mesh bridges Cable bridges are commonly used in telecommunications and fiber optic applications and are installed on short supporting spans of 4 to 8 feet.

Liming can provide customers with cable tray-related solutions according to their needs, and provide necessary technical support for your career development.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

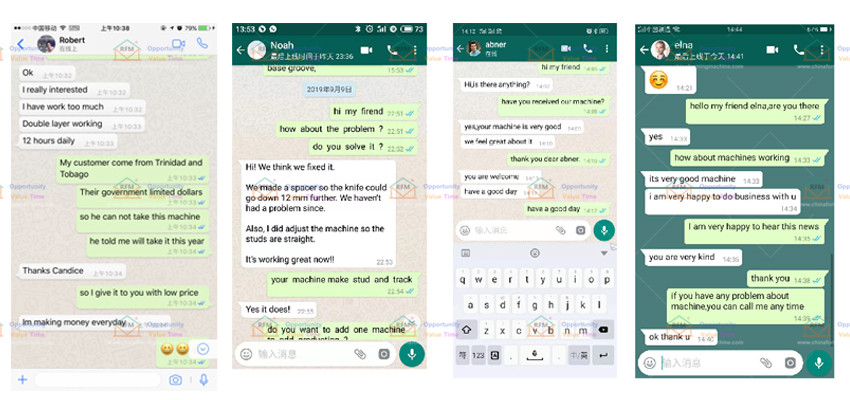

Customer Feedback