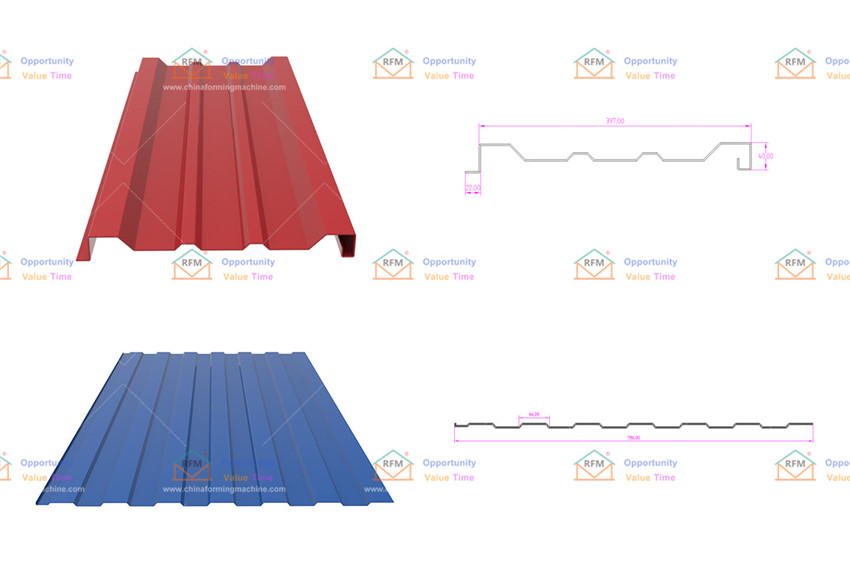

The car panel machine is also called car panel equipment. Its main purpose is to produce car panels, container panels, etc., which are designed and customized according to the thickness, width and peak height of the board. Car roofs, front panels, side panels, and door panels are all made of the new popular glass fiber reinforced plastic panels as the inner and outer skins of the car walls, and the middle layer is a new fluorine-free polyurethane foam material, which is connected to the skeleton through high-strength adhesives, screws, and heat insulation. The thickness of the layer is up to 80-100mm, and the heat insulation performance is good.

The body of the carriage is compact and solid, with high mechanical strength, smooth and beautiful surface, impact resistance, damage and easy cleaning. The refrigerator compartment is composed of fully enclosed panel structure panels, which are bonded by high-strength structural adhesive between the panels. It has large connection reliability and good sealing and insulation performance, and the cabinet body is simple and quick to install.

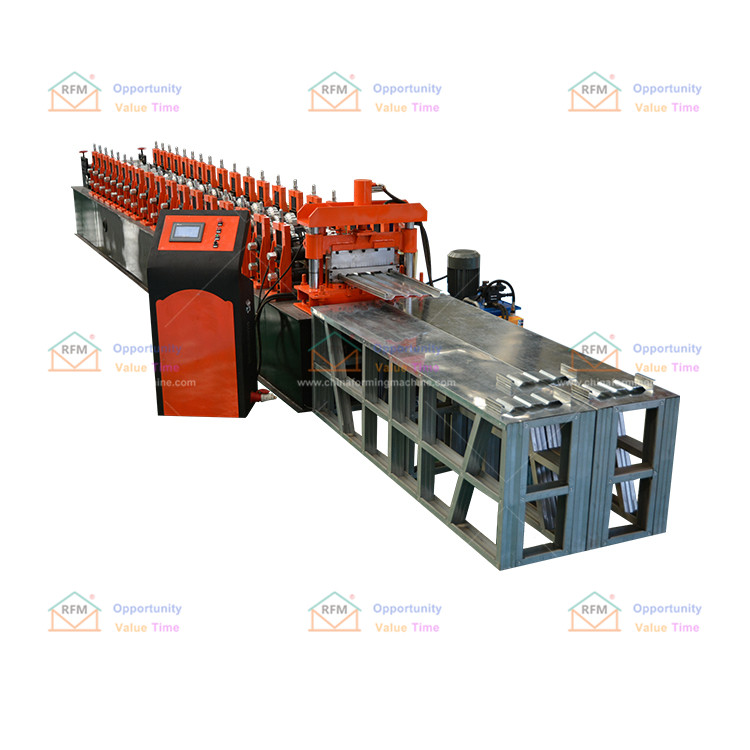

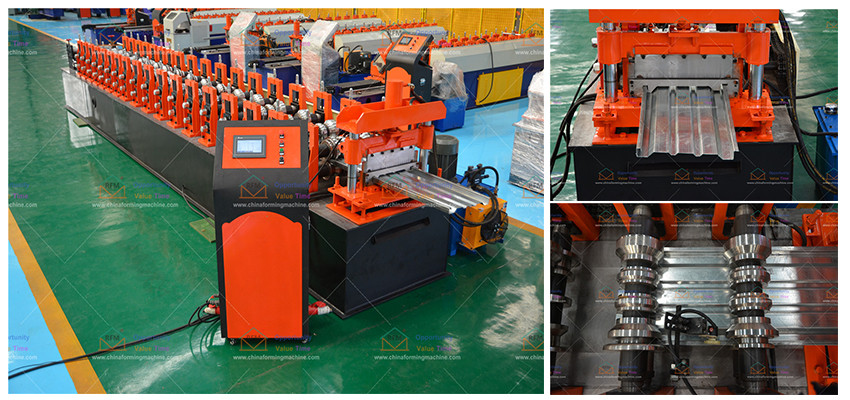

The products produced by the car panel equipment are suitable for various forms of car panels, and specific specifications and models of equipment can be customized according to the specific requirements of customers. The car box plate equipment and the C-shaped steel foundry are the advantages of fast adjustment, fast punching and fast cutting in the same industry. The new butt-adjusting steel sleeve is used, which is simple, fast and firm; the rolling speed is 8-9m/min; The width of the rolled C-shaped steel is 80mm-300mm; the thickness of the rolled material is 1.5mm-3mm (the thickness can also be designed according to the user’s requirements); the secondary molding type is used to ensure the squareness and right angle of the product, and the upper size can be made; Five levels and four levels for leveling to ensure flatness; the base is made of 310H steel; the rollers are made of bearing steel (GR15).

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

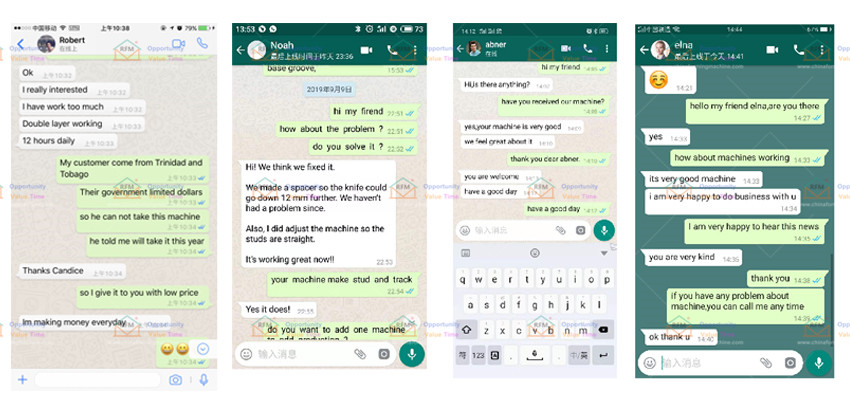

Customer Feedback