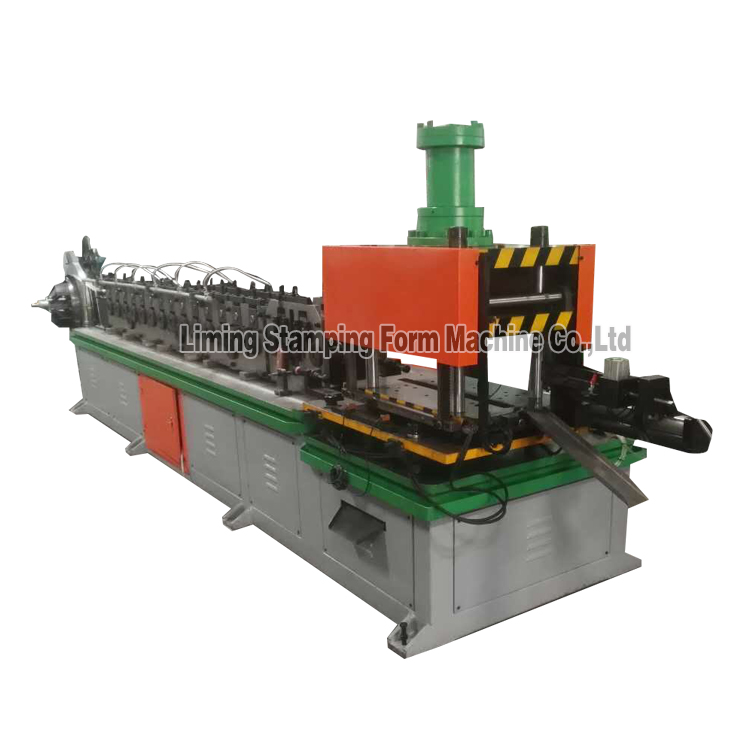

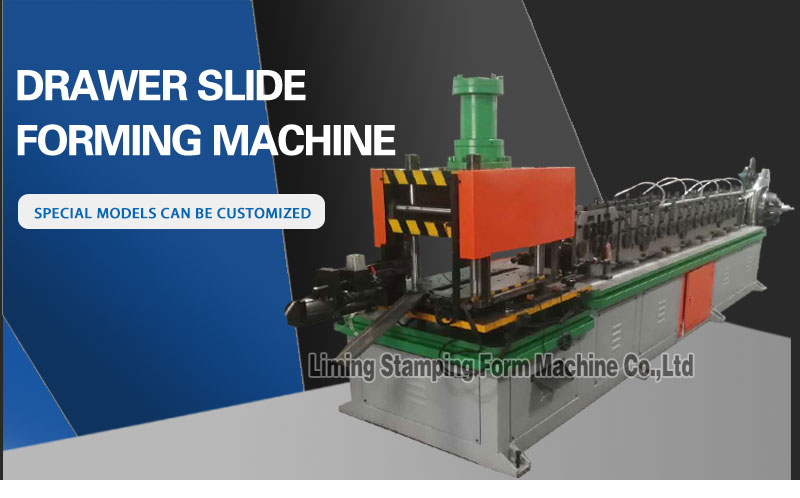

2021 Hot Selling Good quality Furniture Drawer slides roll forming machine

The basic production process of Drawer slides roll forming machine is roll forming, stamping and cut to length. A good slide is determined by smoothness, strict tolerances and load capacity.

Drawer slides roll forming machine production solution:

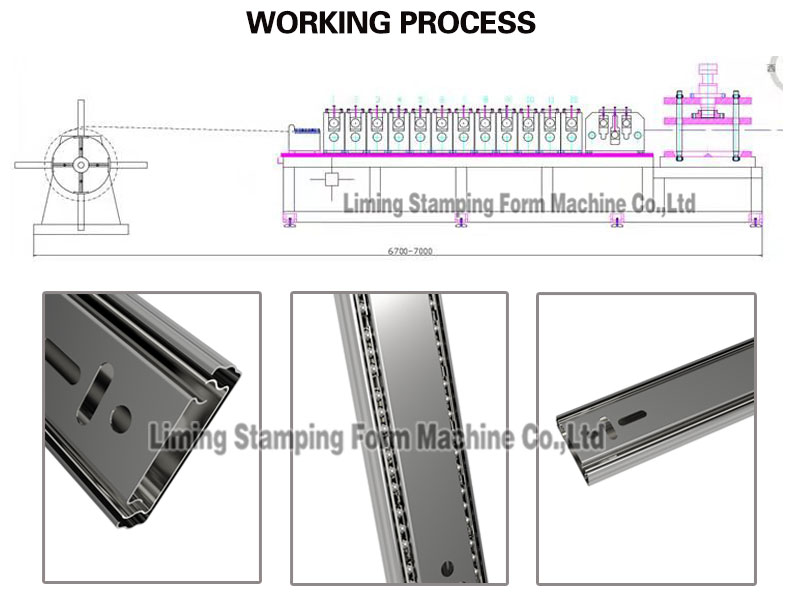

Step 1: Inner Slide/ Middle Slide/ Outer Slide Roll Forming Machine

Decoiler- Feeding- Roll Forming- Straightening- Hydraulic Cut-off

Step 2: Finished CR Slides for Zinc Electroplating Separately ( Excluding)

Step 3: Inner Slide Rivet Fixing Device: Fix the revit on the inner slide

Step 4: Ball Cage Production Punch Line

Motor Decoiling- Feeding- Punching& Cutting

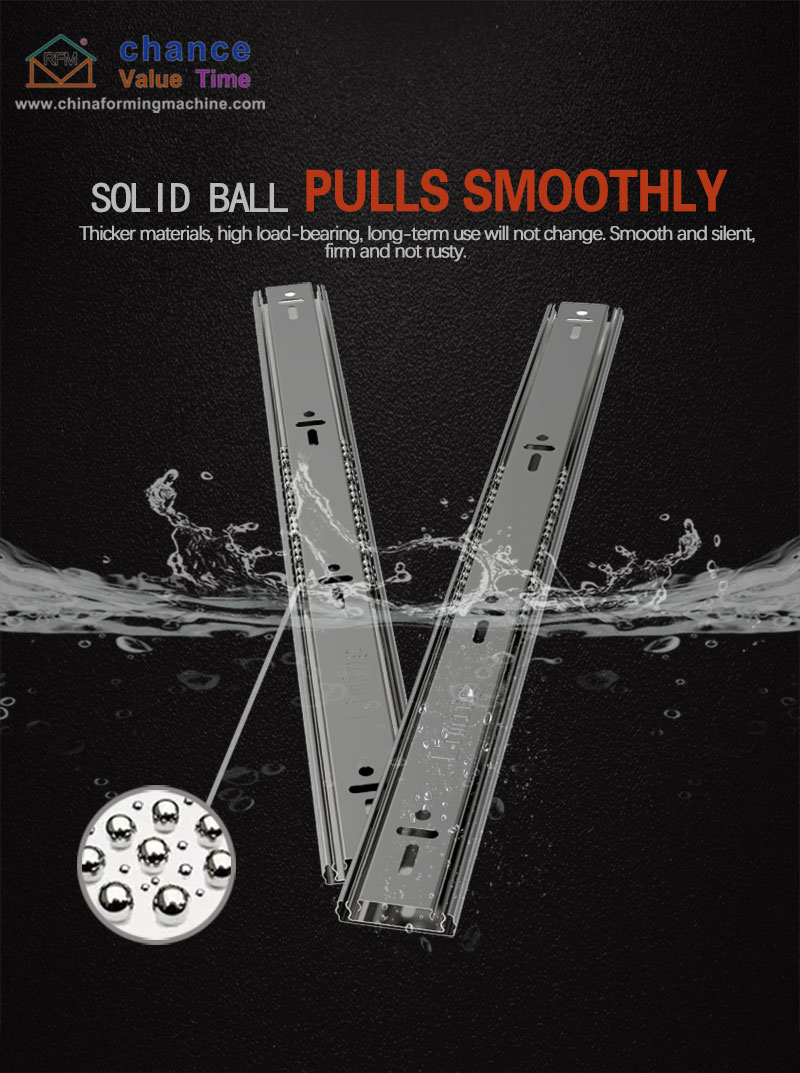

Step 5: Middle Slide Automatic Assembling Line :Middle slide assemble with ball cage & steel balls

Step 6: Manual Assemble Middle Slide Stopper

Step 7: Put Inner slide ( with rivet ) onto the middle slide ( after ball cage assembling)

Step 7: Outer Slide Oil Adding Machine

Step 8: Ball Bearing Press Machine ( Plastic Strip and steel balls)

Step 9: Manual Assembling ( Inner slide& Middle Slide&Outer slide and Plastic strip)

Step 10: QC Adjusting-Check Slide’s Smoothness for Loosing or Tightening

Step 11. Outer slide end bending & Fit End Rubber

1. Are you a trading company or a factory?

-We are an integrated company of industry and trade.

2. Why are your prices higher than others?

-Because we insist on putting quality first in every factory. We spend time and money to develop how to make machines more automated, accurate and high-quality. We can ensure that our machines can be used for more than 20 years without any problems. We can provide 2 years of free quality guarantee.

3. How long can the machine be produced?

-Normally, the welded pipe making machine can be completed within 45 working days. If you need the machine urgently, we can make it for you in less than a month.

4. How to visit your company?

-a. Fly to Beijing Airport: Take the high-speed rail from Beijing South to Cangzhou River (1 hour), and then we can pick you up.

b. Fly to Shanghai Airport: Take the high-speed rail from Shanghai Hongqiao to Cangzhouxi (4.5 hours), and then we can pick you up.