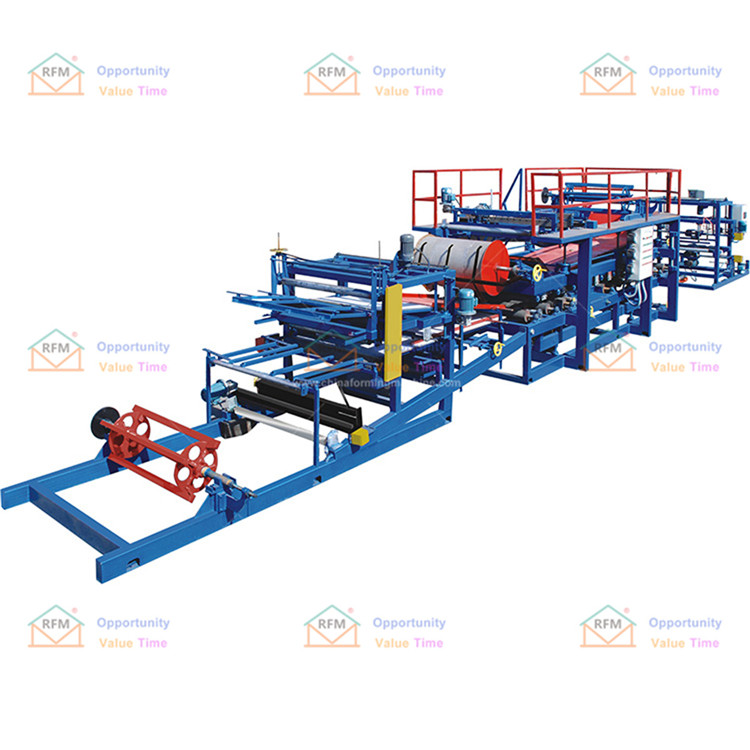

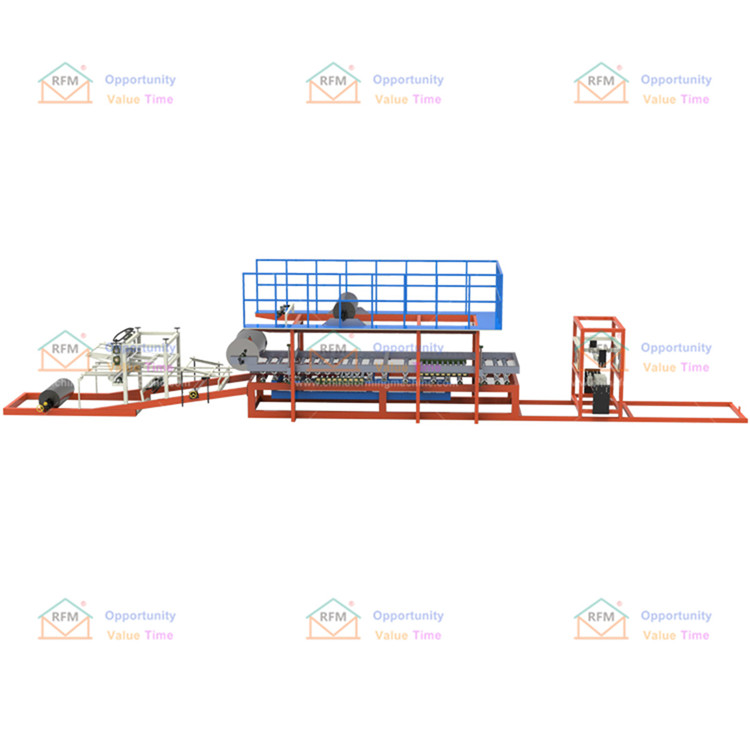

The equipment of the rock wool composite board machine includes a lower panel production area, a core filling area, and an upper panel production area in order from the front to the rear of the conveyor. It is characterized in that the bottom roller of the lower panel production area is a flat round roller. The roller is a round roller with a concave surface, the bottom roller of the pressure roller in the production area of the upper panel is a flat round roller, and the upper roller is a round roller with a convex surface.

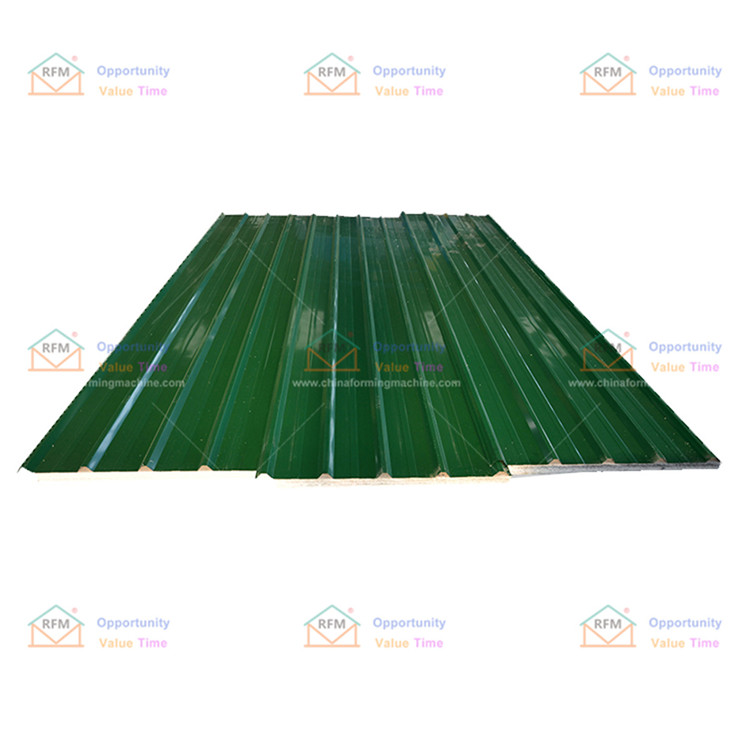

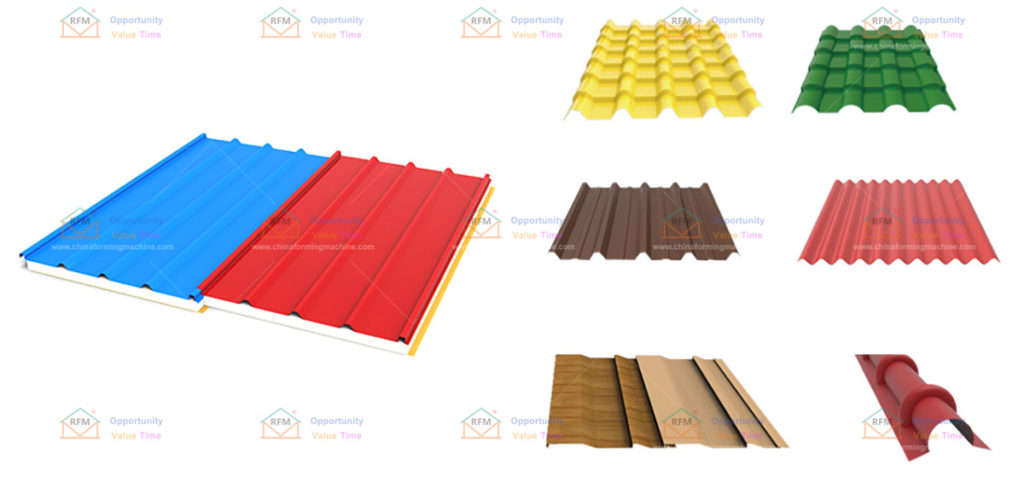

The raw material of the rock wool composite panel machine of the utility model is rolled by the pressing roller in the production area of the lower panel, and the convex surface is pressed, and the core material is filled in the filling area, and in the production area of the upper panel, the concave surface is pressed and rolled by the pressing roller. The convex surface of the panel corresponds, so that the upper and lower panels plus the sandwich layer are combined to form a composite panel with grooves on both sides. The edge of the composite board cut along the center line of the groove is formed into a plug shape, and then a slot is opened on the other opposite side. When the board is connected to the board, the plug side is inserted into the slot side, so that the plug is more secure and overcome The problem of wall cracks caused by the direct seal connection is solved.

Rock wool composite board machine features:

1. The shape of rock wool composite panel machine is beautiful and optimized, with low noise and high production efficiency.

2. The rock wool composite board machine can not only manufacture single-layer laminated boards, but also produce ordinary I-shaped aluminum composite boards and tongue-and-groove inserted composite boards.

3. The main machine of the rock wool composite board machine adopts advanced frequency conversion speed regulation, automatic fixed length cutting.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

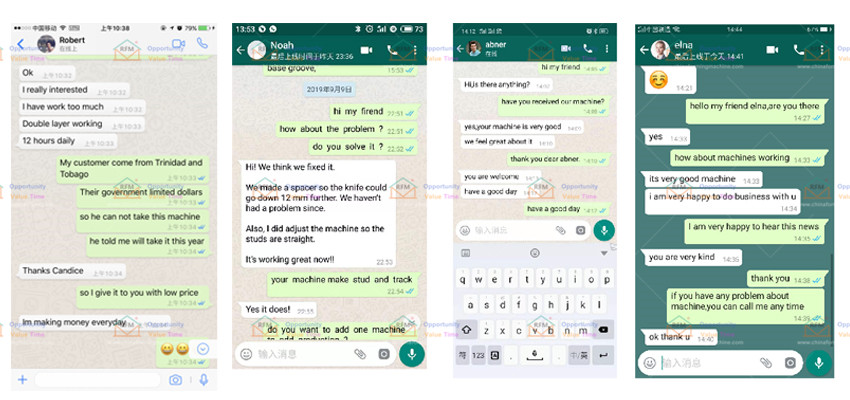

Customer Feedback