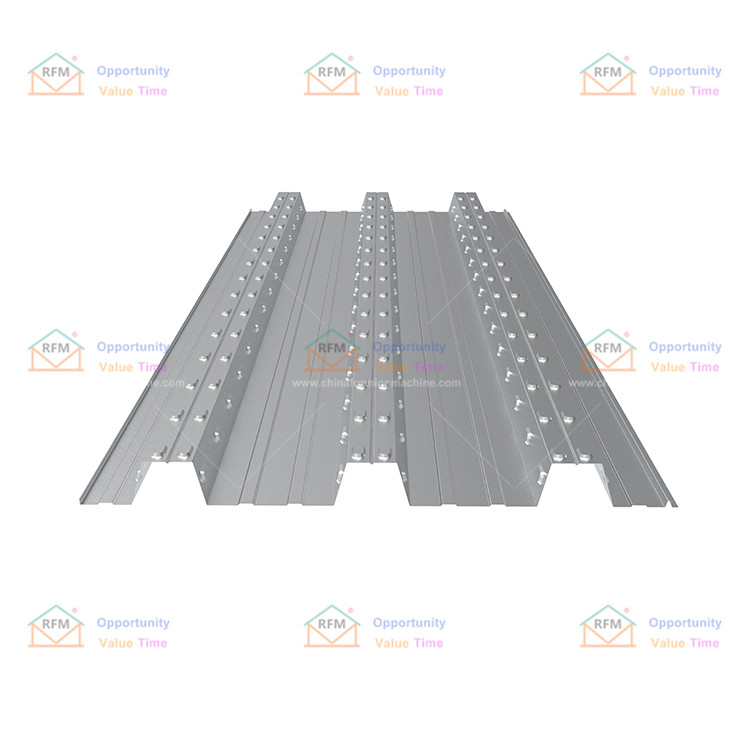

Floor deck is widely used in power plants, power equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminals, train stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, Olympics Stadiums and other steel structures.

To meet the requirements of the rapid construction of the main steel structure, floor deck can provide a firm working platform in a short time, and can use multiple floors to lay profiled steel plates and layer-by-layer pouring of concrete slabs.

Our floor deck roll forming machine adopts advanced design schemes:

The feed design includes:

① Positioning plate: adjust the position of both ends to make it fit the feed width.

②Guide frame: It plays a role of supporting the conveyance of the material roll.

③Guide roller: The design of the upper and lower round rollers makes the feeding process smoother.

The roller assembly includes:

①Roller diameter: φ90mm, 45 # round steel.

②Roller material: hard chrome plating after finishing, mirror polishing, heat treatment.

③ Base rod: φ20 # electroplated round steel to increase the rigidity of both sides of the wallboard.

Post-forming shears include:

①Guide mechanism: double guide column slide rail, stable shear, no deformation of incision.

②Cast iron tool holder: cast iron is processed after stress relief and has strong impact resistance.

③ Blade material: Cr12Mov Shearing life exceeds 1 million times.

④ Rear scissors frame: Q235 steel plate, annealing treatment after rough milling, finishing.

PLC control cabinet includes:

① PLC: Use Schneider high-precision PLC electronic device.

②Inverter: Schneider heavy-duty inverter, running efficiently and stably.

③ Control element: Schneider Electronics, with long service life and low failure rate.

④Touch screen operation: input production data and automatically complete production requirements

Choose high-quality Floor deck roll forming machine , please contact LIMING!

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

Customer Feedback