China Gutter Forming Machine Manufacturer-Factory Price

Click to watch the video

When using the profile produced by the gutter forming machine, the expansion joint or settlement joint of the building should be used as the reverse watershed.

In order to prevent the accumulation of water at the end of the gutter, an overflow port should be set at the end of the gutter, and the bottom of the kicking port The edge is 50-100mm lower than the upper border of the gutter.

Depending on the roof, the cross section of the gutter can be rectangular or trapezoidal. The slope of the gutter should not be too large to prevent the roof cushion from being too thick and increase the load weight of the structure: but it should not be too small to avoid roof leakage and construction difficulties. Generally, the slope should be 0.003~0.006, and the length of the gutter should be less than 50m.

The gutter forming materials used by the construction team generally include: the external drainage system uses the gutter to collect rainwater and snow on the roof and discharge it into the downpipe set on the outer wall. This part of the rainwater is drained into the outdoor rainwater open ditch or underground through the downpipe.

The rainwater drainage system of the concealed pipe; therefore, the gutter drainage system should be composed of gutters, rainwater buckets, downspouts, etc.

Preparation work before construction of gutter forming machine material with convenient construction:

1. The eaves and façades of the ground-floor houses should be flat. There should be no holes, uneven cracks and the appearance of sanding, and they should be clean and flat.

2. Before construction, use a shovel and a broom to smooth out the protrusions, mortar bumps and other foreign objects on the eaves of the nearby low-level houses, and clean the general affairs. To prevent falling into the gutter.

3. Mokai rain gutter is selected as the gutter material for the eaves, and it is laid flat on the eaves surface, and then the gutter is installed.

A guaranteed gutter forming machine manufacturer can guarantee the length of gutter products during production, so that not only the products produced are easy to sell, but also the installation workers can quickly install them during construction.

The gutter forming machine and downpipe should be used in combination. If only the gutter forming machine is produced, then this factory is not a well-guaranteed supplier for the entire gutter industry.

LIMING roll forming machine company can manufacture high-quality and reasonable price fascia machine, gutter forming machine, downspout forming machine, you can enjoy one-stop shopping here at LIMING.

We have sold semi-circular gutter forming machines, square gutter forming machines, fascia cover machines, downspout forming machines, etc. to Romania, South Africa, Brazil, Europe and many other places.

Provide Installation Method & Customized Profile For Free

|

1

|

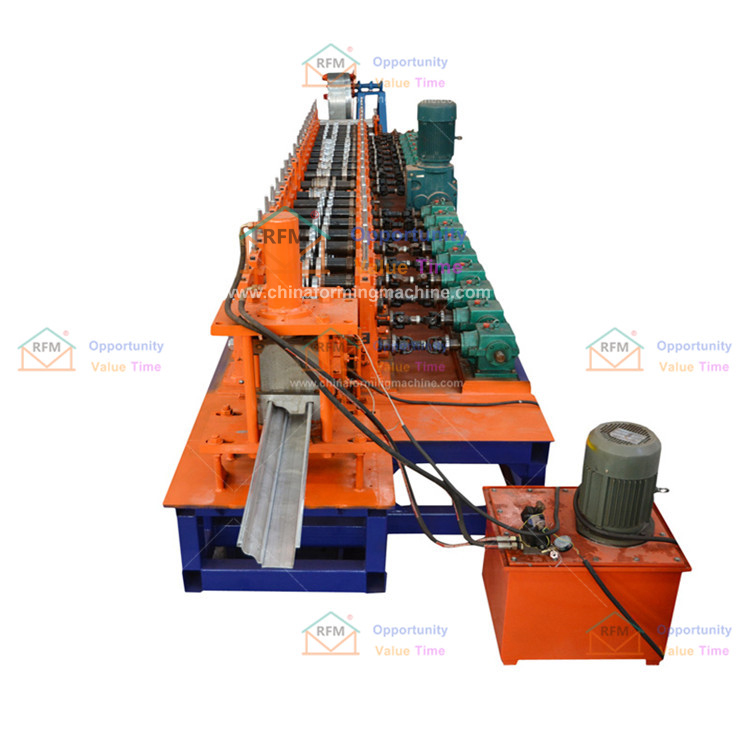

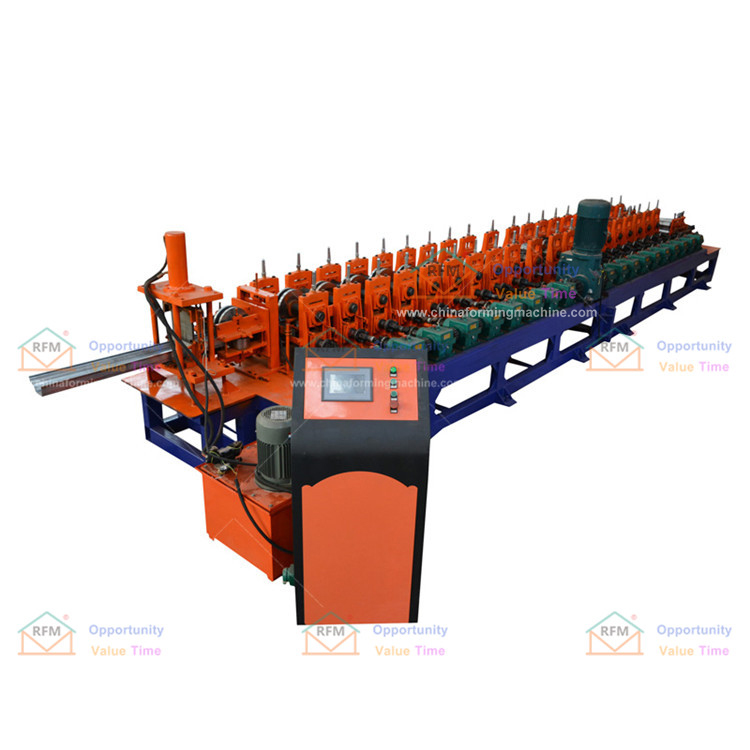

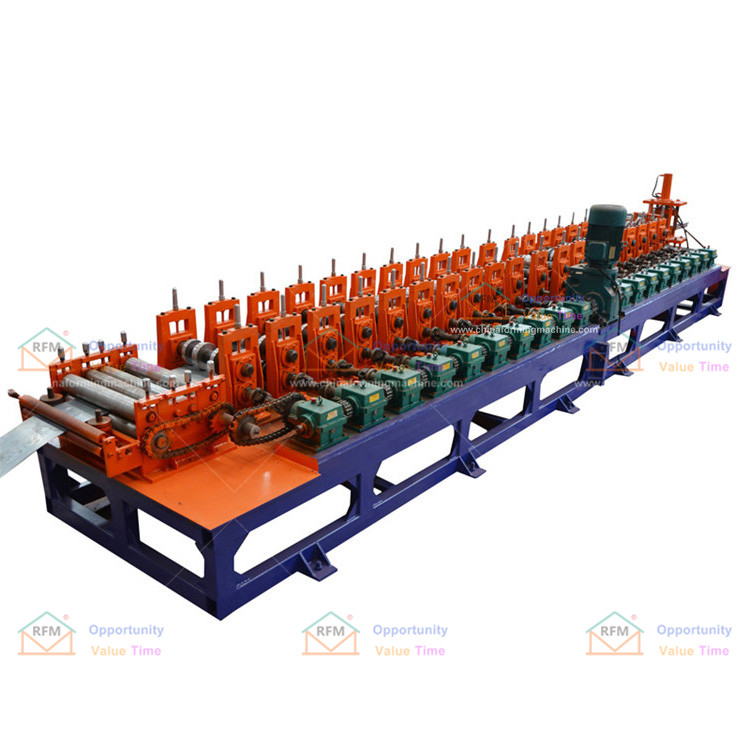

machine name

|

Self-propelled U-channel roof tile gutter roll forming machine

|

|

2

|

Width of the feeding material

|

make as customer need

|

|

3

|

Roller station

|

16 rows

|

|

4

|

Thickness of feeding material

|

0.3-0.8 mm

|

|

5

|

Productivity

|

15-22m/min

|

|

6

|

Rollers’ material

|

45# steel

|

|

7

|

Diameter of shaft

|

65mm

|

|

8

|

Voltage

|

380V 50Hz 3phases

|

|

9

|

Wall thickness of main forming machine

|

16 mm steel plate

|

|

10

|

Main forming machine body

|

350 mm H steel

|

|

11

|

Main Motor power

|

11 kw

|

|

12

|

Size

|

9000*1100*1400mm

|

|

13

|

Weight

|

About 4 T

|

|

14

|

Custom

|

According to customer’s requirements

|

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.