Light Gauge Steel House Machine for Prefabricated House of C89 Frame CAD Machine

Light gauge steel house machine Cold Roll Forming is to install multiple sets of (upper and lower) roll forming dies in a certain order, and pass the corresponding metal steel strip coils through the roll dies with specific contours in a continuous manner to roll It is made into a flexible processing technology consistent with the designed shape.

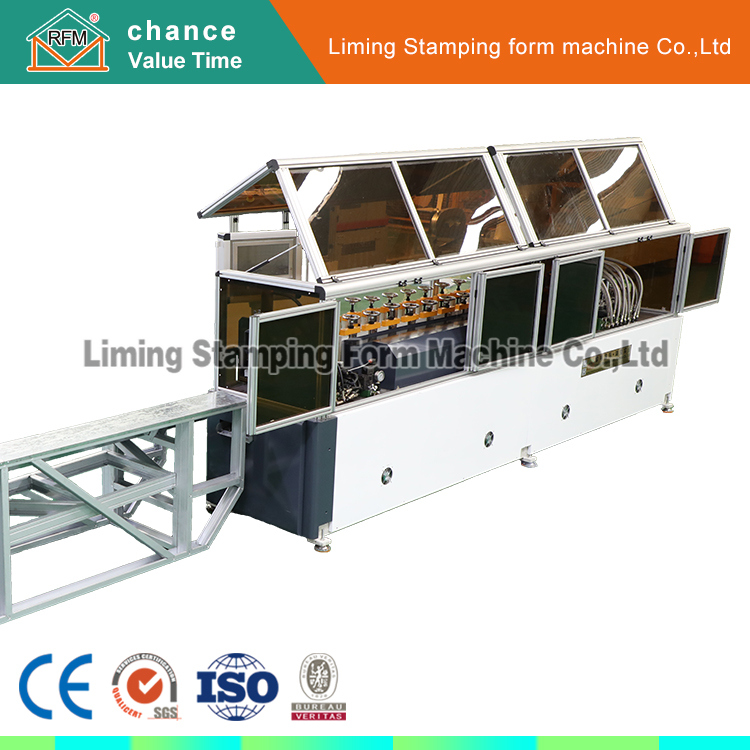

LiMing light gauge steel house machine components include automatic material unwinding and unwinding machine, material leveling device, forming host, automatic punching, cutting, receiving table and computer control cabinet.

The light gauge steel house machine automatic punching device is equipped with: screw holes, chamfers, web through holes, small edge cutting, pipeline holes, web shrinking, cutting and other punching dies and coding devices. Using professional-grade industrial computer CNC automatic control, it has the characteristics of wide range of use, high product accuracy, high degree of automation, material saving, and high degree of automation. It is designed according to customer requirements for the continuous innovation of prefabricated buildings in the current market and the structural form. Manufacture special roll forming machine equipment for special requirements.

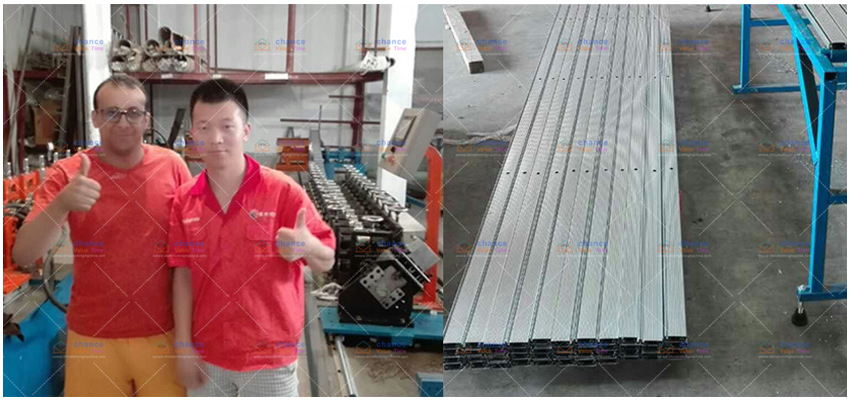

Mr. Kevin from Egypt is a local supplier of Light steel materials. In the near future, he wants to open up new markets for light steel keels. Through the introduction of old customers, he found us and learned relevant industry knowledge.

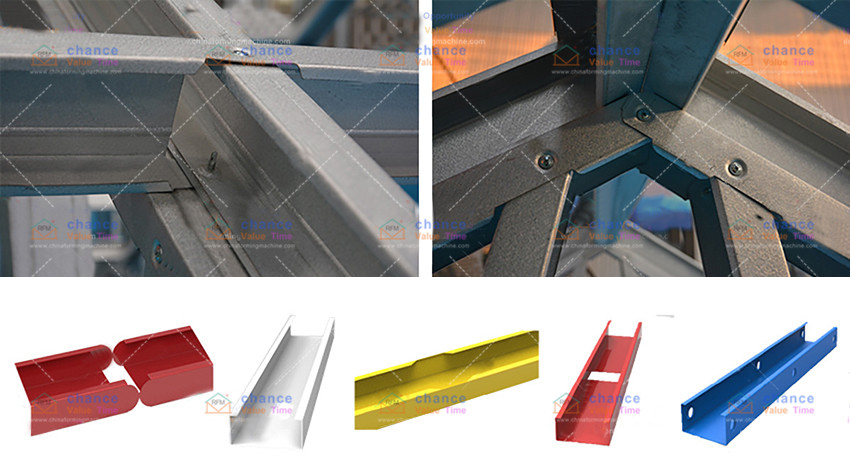

Light steel keels are used to decorate non-load-bearing walls and building roofs with lightweight cardboard (such as plasterboard and decorative plasterboard). It is suitable for the shape decoration of the roof of various buildings, the inner and outer walls of the building and the basic material of the scaffold ceiling. According to its use, there are ceiling keels and partition keels. According to the cross-sectional form, there are V-shaped, C-shaped, T-shaped, L-shaped and U-shaped keels.

During the introduction, we recommended this high-speed production light gauge steel house machine to him. The whole set of equipment is fully automatic, high-precision computer-controlled automatic processing and production, driven by imported high-speed, high-precision servo motors, and the production speed can reach 50-70 meters per minute! At the same time, the speed is fast, the machine runs stably, and the finished product size is standard; the machine is easy to operate, just input the data of the required size in the computer controller, and the machine will automatically generate it with one button. The standard computer controller can input multiple Various data sizes, Chinese and English combination, simple operation.

Each pressure roller of the light gauge steel house machine is equipped with a manual wheel, which is convenient to adjust; after the coil is formed, the machine will automatically cut and cut the size, and the plate part is neat and free of burrs. In addition, I also introduced our team to him. We not only produce equipment, but also have our own design team and construction team. Our professional team will let you know how to design, produce and assemble equipment partitions. All these only need to know some parameters in your information, you can clearly know the most suitable machine for you.

After a detailed introduction, we also hope that he can visit in person after the epidemic is over, and we will lead him to visit our factory to further demonstrate our strength!

If you have any questions about Light Gauge Steel House Machine , you can contact us

Liming Stamping Forming Machine Co.,Ltd provides various roll forming equipment for sheet metal processing, mainly for customers in construction, cold bending, power generation, agriculture, electronic technology and other industries.

Liming Stamping Form Machine Co.,Ltd was established in 1996. It is a developing modern company, mainly producing and selling:

roofing sheet making machine

shutter roll forming machine

cz purlin roll forming machine

Gutter roll forming machine

Cable roll forming machine

Coil processing equipment

Stud and Track roll forming machine

sandwich panel roll forming machine

solar photovoltaic panel roll forming machine

Slitting line

Other construction material production equipment.

Production standard and customized production lines.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

Customer Feedback