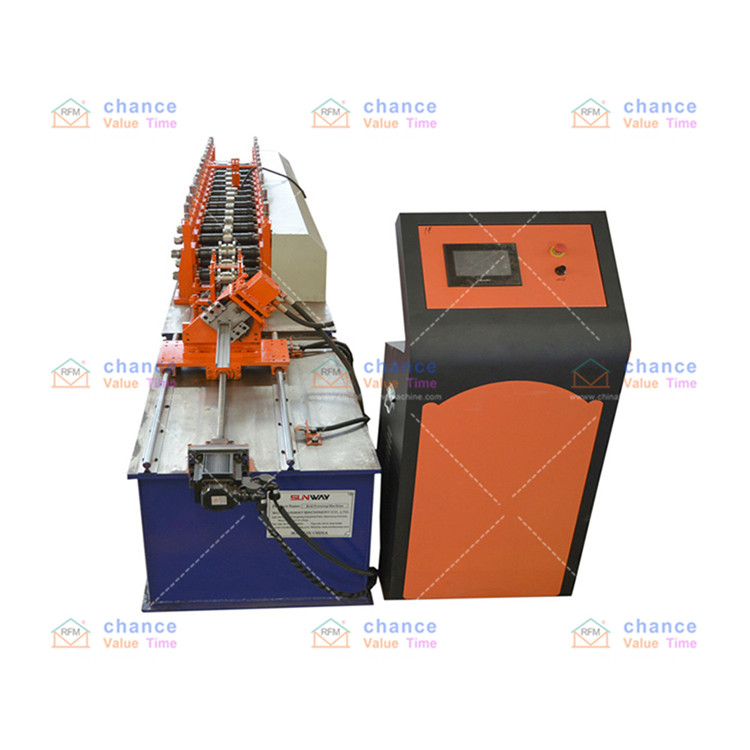

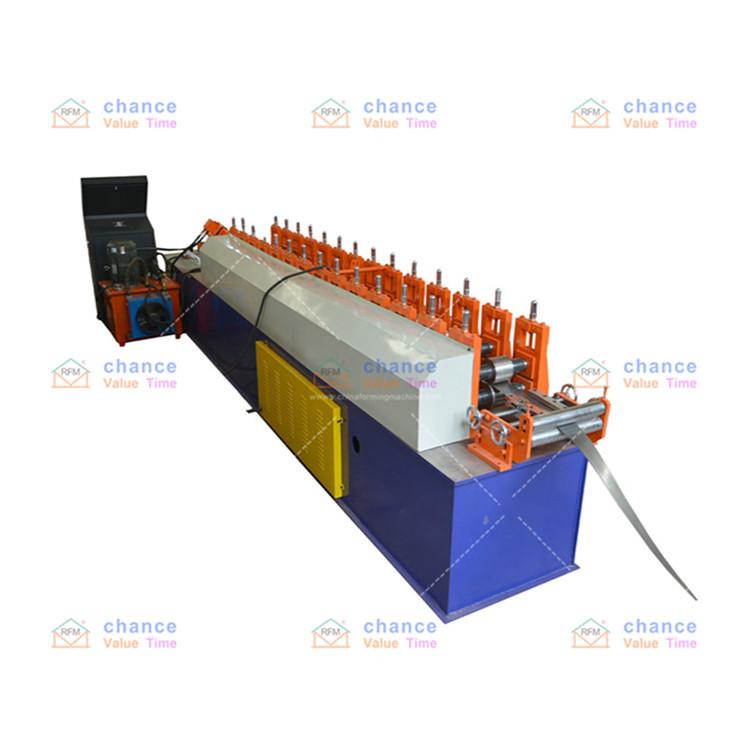

Why we offer the final product application they purchase High Speed Partition Wall Keel Roll Forming Machine from us?

For each our customer, Will offer them the final product application solutions when we cooperate with them, you may ask that does this have anything to do with customers?Of course it does, so that the customer can know exactly how the products he produces are applied. He also knows what he should pay attention to in the production, and he can also tell his customers what to pay attention to in the application. This will allow his customers to trust him more, and will also play a role in boosting his sales. And also can help to test the Keel Roll Forming Machine manufacturer precision.Such as the steel trusses produced by the Partition Wall Keel Roll Forming Machine, When installing the keel partition wall, pay attention to the following points: 1. Before installation, do a good job in the elastic line work, along the ground, along the edge of the top keel and the elastic line, the fixed point spacing between the keel and the base At least greater than 1m. 2. When the keel is installed vertically, it must be kept absolutely vertical. In the case of damp rooms or steel mesh plastering walls, the distance between the keels should be greater than 400mm. 3. Install the support keel to install the support card in the direction of the opening of the vertical keel, the distance is 400-600mm, and the distance from the two ends of the keel should be controlled at about 20-25mm. 4. If it is a through-type keel, a partition wall less than 3 meters will be installed. If the height exceeds 3-5 meters, two channels can be installed. 5. When the decorative panel is not on the ground or along the top keel, use the cross brace to fix it.

Please do not hesitate to contact us if interested in the machines, our technical and design team will offer the 24 hours service for you.

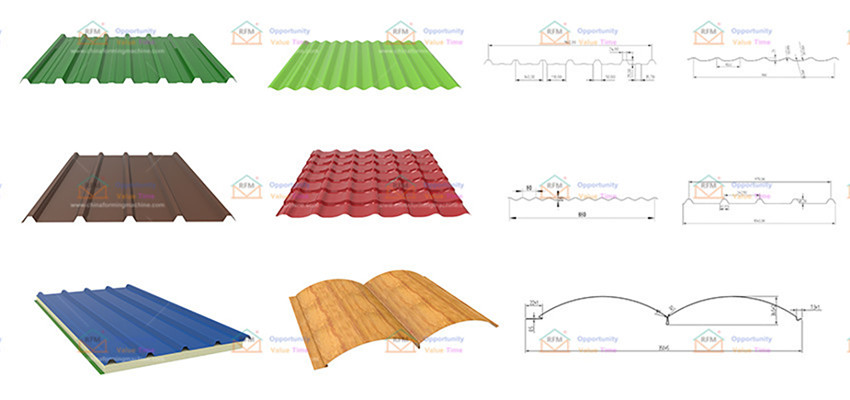

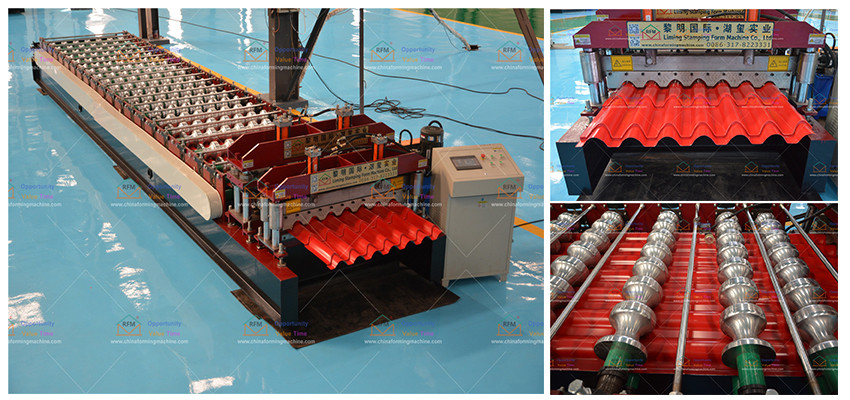

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

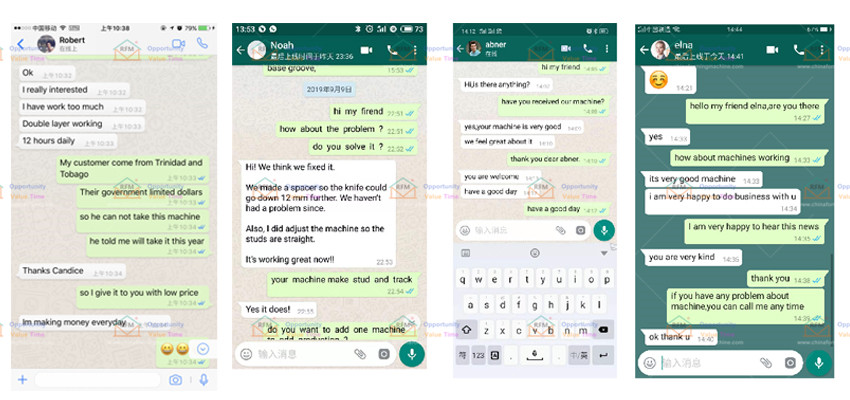

Customer Feedback