More information about perforated cable tray

The perforated cable tray is a cable tray with holes on the bottom plate and side rails for laying power and signal cables. The purpose is to distribute power and send signals in factories, department stores, stadiums, hospitals, airports and other industries. Compared with the channel cable tray, the bottom of the porous cable tray has holes to help ventilation.

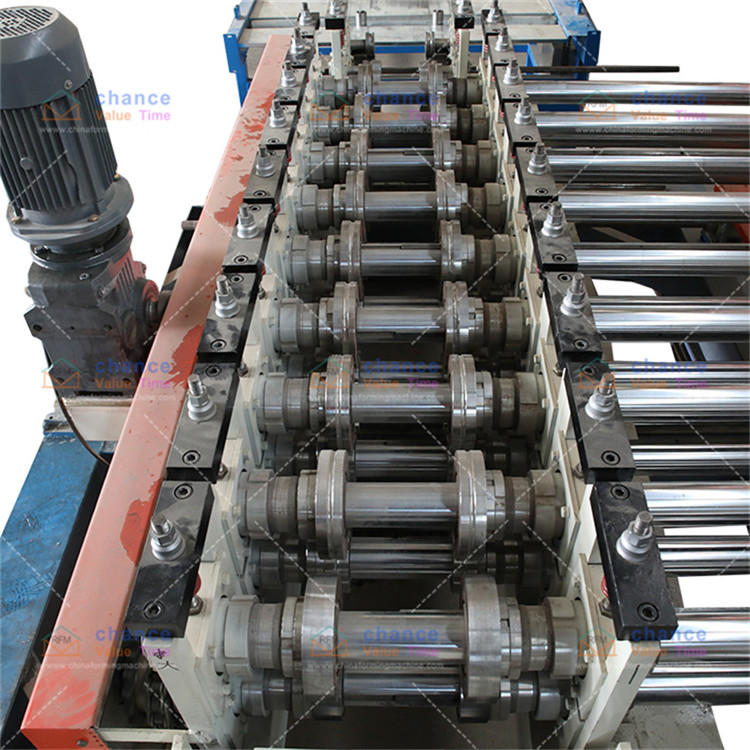

Compared with ordinary welded wire mesh cable trays and wire troughs, stainless steel perforated cable trays have stronger support for cables. Liming provides cable trays with holes (welded cable trays with holes, bolt and nut cable trays with holes). The solid metal cable tray is made of perforated perforated stainless steel or galvanized carbon steel plate. The holes can be round, square or triangular for ventilation, with various opening sizes and plate thicknesses. Stainless steel perforated cable tray is anti-rust, suitable for outdoor telecommunication purposes.

The perforated cable tray is made to pull the cable smoothly and easily from one point. Liming designs the cable tray by considering the cable load and actual field problems. All accessories are made of the most advanced single-piece structure as much as possible. The grooving method makes it easy to cut and connect at any position without the need to drill on site. The design allows for greater cable filling capacity and smooth turns at elbows.

characteristic:

●Sturdy structure, can carry all types of cables.

●There are holes at the bottom of the multi-hole cable tray, which can provide enough ventilation and position for the cable.

●Pre-galvanized, hot-dipped powder coating, and epoxy coating after completion, it can prevent corrosion, fire and moisture.

●Excellent heat dissipation.

●Safe, smooth edges can protect the cable from scratches.

●Strong enough to withstand short circuit.

●Flexible, convenient and fast installation

●Provide various accessories to fix and install

●Easy to maintain.

●Long service life.

Application of porous cable tray:

Several types of trays are used in different applications. The sturdy bottom bracket provides maximum protection for the cable, but requires cutting the bracket or using accessories to enter or exit the cable. The deep and strong shell of the cable is called the cable channel or cable trough. The ventilated tray has an opening at the bottom of the tray to allow air around the cable to circulate, drain and allow some dust to fall off the tray. Small cables may flow out of the tray through the ventilation holes, which may be slots or holes punched in the bottom.

The cables on the ladder tray are supported by cross bars, similar to the steps of a ladder, with intervals of 4 to 12 inches (100 to 300 mm), and the width of the ladder is 100 mm to 1000 mm.

Ladder-shaped cable trays and ventilated trays may have a firm covering to protect the cables from falling objects, dust and water. Tray covers used outdoors or in dusty places may have sharp shapes to drop debris including dust, ice or snow. High-power cables placed in the bracket may require support blocks to maintain the spacing between the conductors to prevent the wires from overheating. Smaller cables may not be fixed in the horizontal bracket, or they may be fixed to the bottom of the vertically installed bracket using cable ties.

In order to maintain the support of the cable when the height or direction of the cable rack changes, each style and manufacturer has manufactured a large number of compatible dedicated cable rack accessories. The horizontal elbow can change the direction of the tray in the same plane as the bottom of the tray, and it can be made into shapes of 30, 45 and 90 degrees. The inner and outer elbows are used to change perpendicular to the bottom of the tray. These can be in various shapes, including T-shaped and cross-shaped. Some adjustable elbows can be used for field installation of pallets around obstacles or irregular shapes. The cable tray uses various clamping, supporting and splicing accessories to provide a complete functional tray system. For example-cable trays of different sizes used in one operation can be connected with reducers.