What is stud and track roll forming machine?

The LIMING stud and track roll forming machine is a precision flying shear that can produce precision tolerance parts on materials of various widths and specifications.

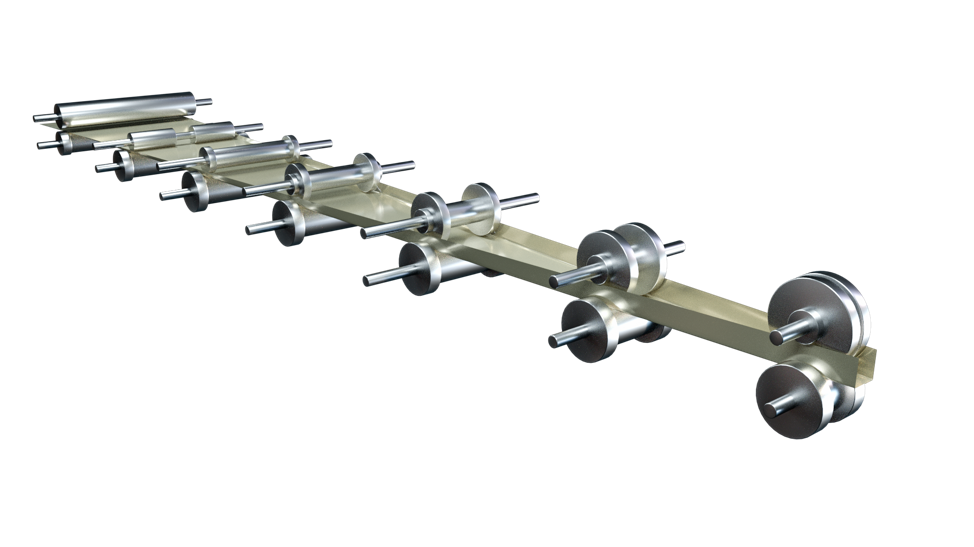

The machine structure steel frame roll forming line can change the profile size through the computer keys within 1 minute without changing tools or gaskets; the maximum speed can reach 150m/min

Article Quick View >>

1. Classification of stud and track

2.stud and track roll forming machine structure

3.How does the stud and track roll forming machine work

4.How do I choose the roll forming machine that suits me

5.Liming roll forming machinecompany introduction

What is a stud and track roll forming machine?

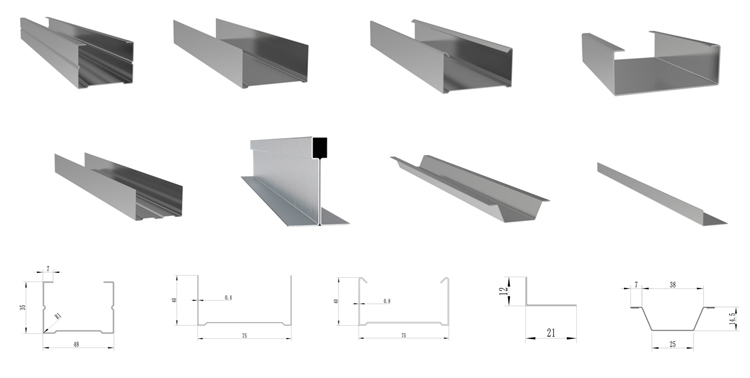

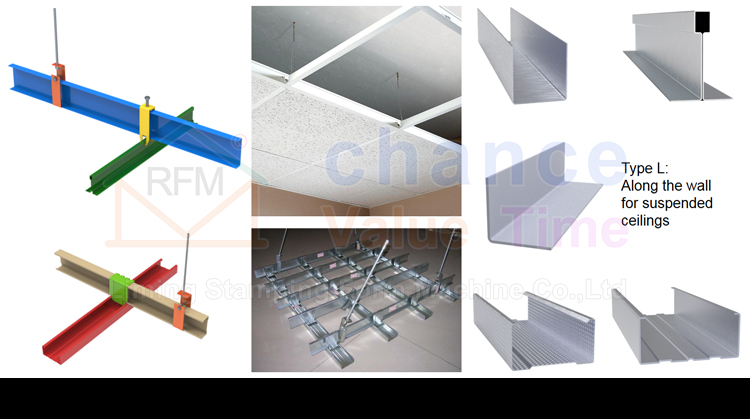

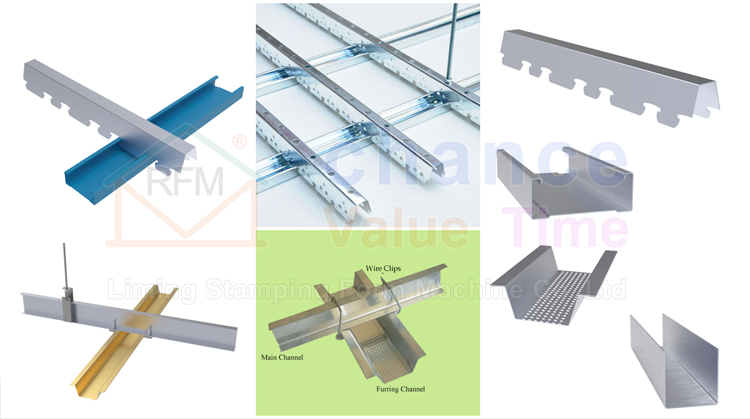

The machine uses strip steel as raw material, through continuous cold rolling, to produce complex cross-section profiles. The products are generally used for house partitions, partition walls, ceilings, corners, etc. (products include: light steel keel, paint keel , Cassette keel, C-shaped U-shaped L-shaped various building profiles, etc.) Different specifications of cold bending and baking paint unit equipment are controlled by PLC.

1. Classification of stud and track:

1. Light steel keels are generally divided into wall keels (C) and ceiling keels (U).

The main specifications of the wall keel are divided into C50, C75, C100 and C150.

The main specifications of the ceiling keel are divided into U38, U50 and U60.

The machine is divided into:

stud roll forming machine

track roll forming machine

omega keel roll forming machine

Ceiling T grid roll forming machine

Metal steel wall bead corner corner roll forming machine

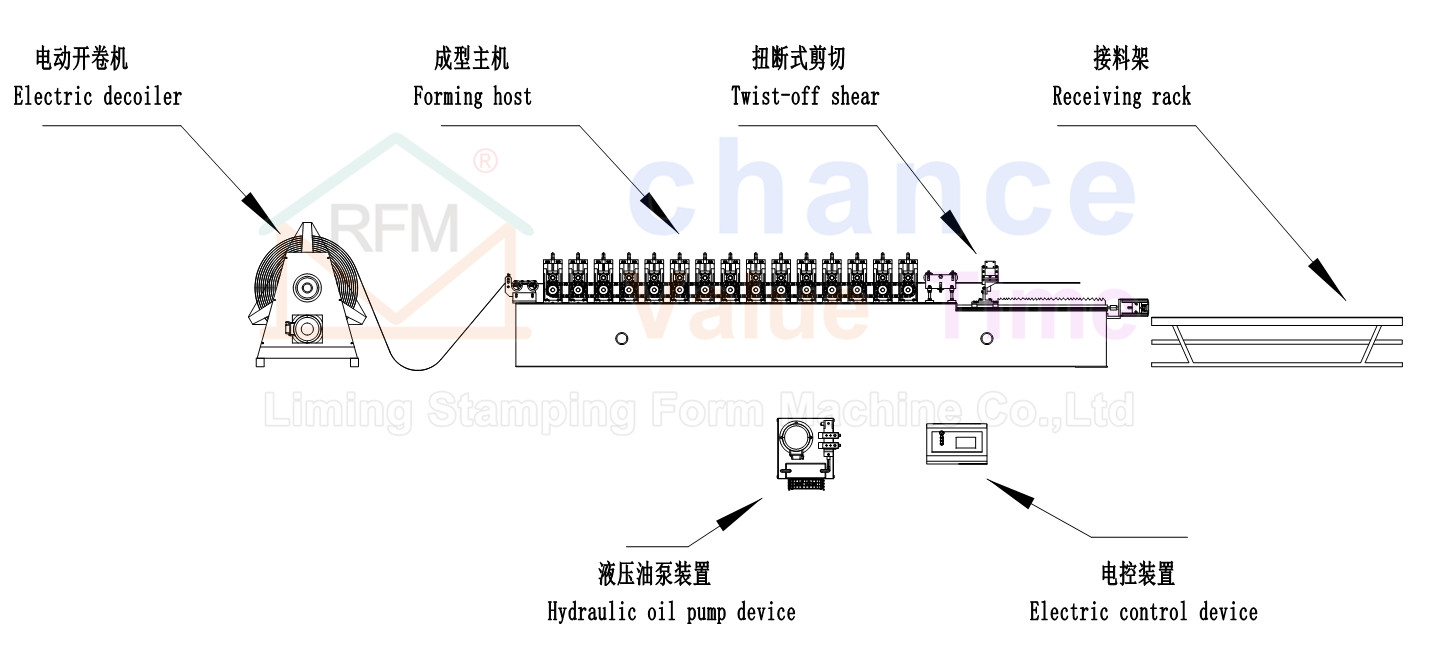

2.roll forming machine structure:

3.How does the stud and track roll forming machine work?

The stud and track roll forming machine can be divided into:

Ordinary 20m/min roll forming machine

50m/min roll forming machine

100m/min roll forming machine

Adjustable size roll forming machine (please contact us if necessary)

4.How do I choose the roll forming machine that suits me?

If you have these problems, we can provide you with solutions

1. I don’t know the product, I have been recommended by someone, and want to start a business (recommended version, which can provide some popular products in the market. Can provide investigation and analysis services)

2. We are a distributor of machines and want to find more high-quality products

3. I am a machine retailer and do not have my own machine, but I have certain product knowledge, but I need to recommend the machine

4. I am a middleman who wants to sell machines, but I don’t know how to choose?

We can provide machine solutions for machine manufacturers, import profile traders, construction project companies, etc.

Our company possesses the international first-class technical team and strives to tackle the difficulties in production efficiency and labor saving. As the “High-Tech Enterprise”, Liming has undertaken the mission of “China Building Materials Machinery R&D Center”. The models including CNC50 and CNC100 promoted by us have solved the low speed problem of 15 meters and 30 meters in the ROLL FORMING MACHINE industry.

CNC50 machine and CNC100 machine have obtained 16 patents with the efficiency 3 times and 6 times that of similar machinery in China, and it is completely in line with the speed of European high-priced machinery. The time of automatic cutting machine is only 0.15ms.The machines boast moderate price, and customers which launch new projects will not exceed the budget due to the price reason. The speed of one set of machinery = the output of 3 sets of machinery, which allows you to surpass the competitors and help you win the order with fast delivery.

The latest LOCKHEER stud and track roll forming machine is equipped with a gearbox transmission structure, which is more stable in operation, with a high-power motor, and a production speed of 100m/min, which can run for a long time.

Our machines are exported to Europe, Egypt, Dubai, South Africa, France, Britain and other countries in large quantities every year; some distributors purchase multiple roll forming machines every year, and they will come to China every year to learn the latest technology and purchase the most high-end machines.

Such a good roll forming machine must be delivered to you perfectly, which is the most important result of our QC team that strictly controlling every detail. For the high-quality machinery, in the strict production process, our QC will classify the backup files for each of DV and images of the mechanical package and reinforced package, and send to customers & partners and production managers by E-mail, and hand over the “Mechanical Archive Manual” to the customer with the container.

Liming Stamping Form Machine Co., Ltd. was established in 1995. After 27 years of unremitting efforts, it has been developed from the state-owned old factory with 8 employees to the current group with 360 employees and the overall solution provider for industrial chain customers with various roll forming machines.