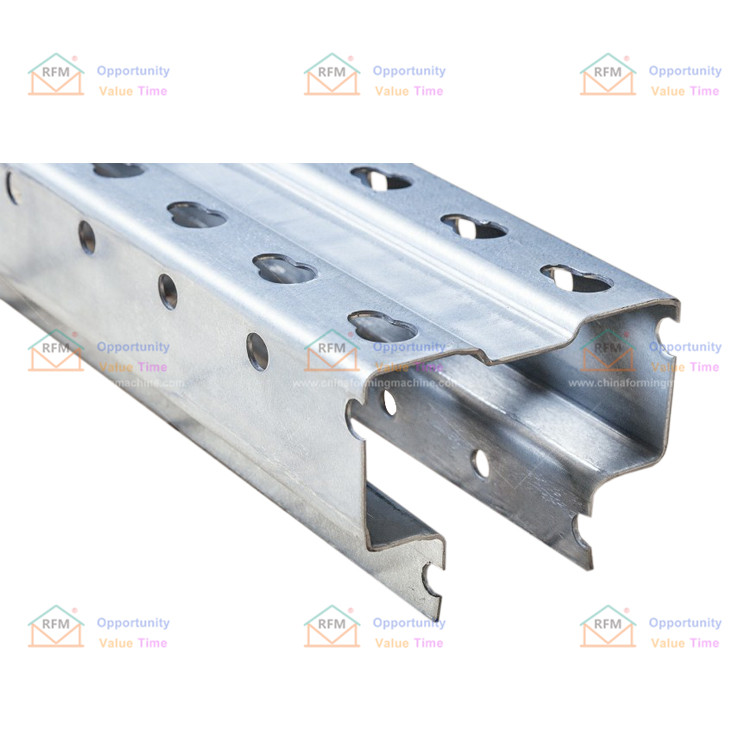

Manufacturer of high speed punching shelf post forming machine

LIMING shelf post forming machine complete solution products include: shelf post machine, shelf column forming machine, shelf beam machine, shelf pillar forming machine , shelf shelf panel production line equipment and other products.

Supermarket shelf post forming machine, supermarket shelf forming machine equipment, supermarket shelf production line equipment

Shelf cold formed forming equipment products include: shelf column equipment, shelf column forming machine, shelf beam equipment, shelf pillar forming machine equipment, shelf shelf panel production line equipment and other products.

2. Production process

The use of shelf post forming machine to produce shelf profiles has low production costs, high efficiency, and environmentally friendly materials. It can be combined with production needs to manufacture automated production equipment, save labor, and make enterprises more competitive in the fierce market competition.

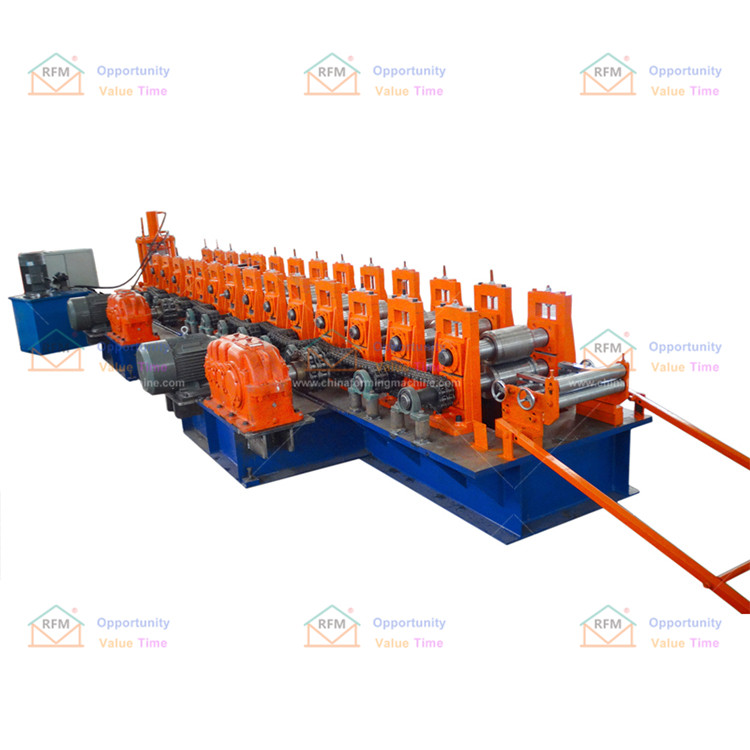

LIMING shelf post forming machine is composed of: discharging, leveling, feeding, punching, forming machine, fixed-length cutting, receiving platform, electric control box (PLC control), etc.

shelf post forming machine

The shelf forming equipment is controlled by PLC.

Automatic discharging-guide-leveling, feeding-continuous bottom hole-forming-fixing, cutting-receiver during forming process

Cold Roll Forming Machine After Shelf

Equipment performance:

1. Unit rolling capacity: width ≤400mm, plate thickness 1-2.5mm

2. Production speed: 0-15m/min

3. Forming host: a model: GY160 b frame structure: cast iron arch (material HT200) gantry c transmission mode: each independent gear distribution box transmission d roller material: GCr15, quenching treatment, hardness HRC58-62o

LIMING cold formed forming machinery and equipment manufacturer. The company specializes in the research and development, design, manufacturing, sales, and foreign trade of cold-formed steel and non-standard steel structure products. It is also one of the professional manufacturers of cold-formed steel equipment in East Asia, South Asia, and ASEAN. , Eastern Europe, CIS, Oceania, South America, Latin America, the Middle East, South Pacific, Africa and other places. We look forward to working with you and welcome to call and visit our factory. At present, our company has successfully manufactured the following cold bending equipment:

1. Elevator profile production line.

2. Fireproof rolling shutter frame production line.

3. Automobile profile production line.

4. Production equipment for electrical cabinet profiles.

5. CZU series cold formed steel unit.

6. Cable tray cold formed steel unit.

7. Solar photovoltaic support production line.

8. Shelf particles/beams/laminating equipment.

9. Floor molding machine production line.

10. Pedal series cold-formed steel unit.

11. Three-dimensional garage side beam/wave board production line.

12. Color steel tile and glazed tile forming production line equipment.

13. Equipment for welding H-shaped steel corrugated web production line.

14. Light steel keel series profile cold forming unit.

15. A complete production line for highway guardrails.

16. Steel silo production line culvert corrugated board equipment.

The cold roll forming equipment produced by our company has the following advantages:

1. The equipment is controlled by PLC, and multiple safety protections are set during normal production.

2. The bed is welded by steel plate. It is also tempered to eliminate internal stress and avoid deformation of the fuselage.

3. The forming frame is of cast iron structure and tempered. High strength and long service life.

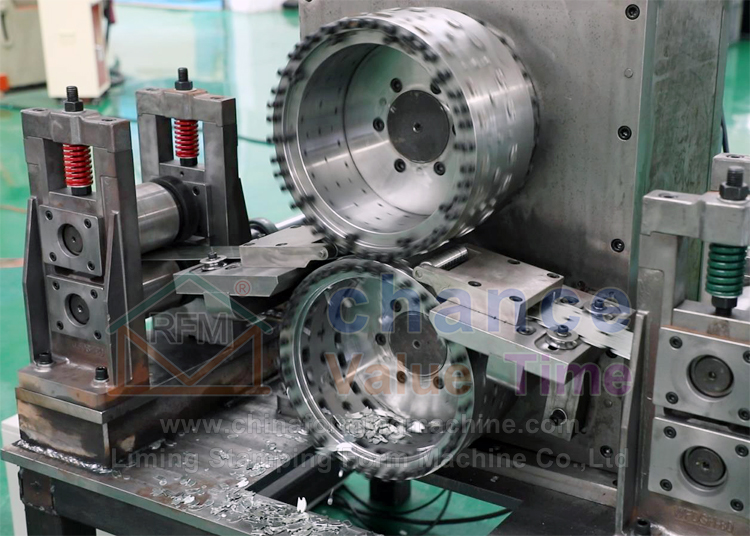

4. The material of the roller is 40Cr, and the hardness after quenching and tempering is HB280.

5. The material of the forming mold is GCr15, quenched, and hardness: HRC 56-62℃.

6. The transmission structure is gear box transmission. Each forming frame has a gear box to ensure overtime, high-strength operation and long service life.