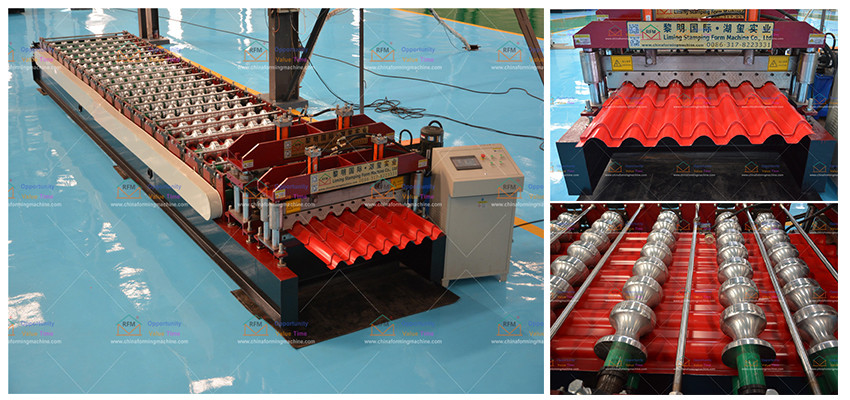

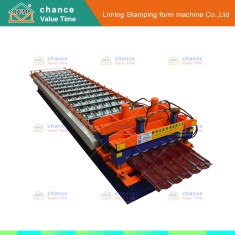

The 828 antique glazed tile machine adopts a new hydraulic shearing system. The equipment includes a forming host, a hydraulic station, a discharge rack, a forming shear, a control box, and a discharge rack.

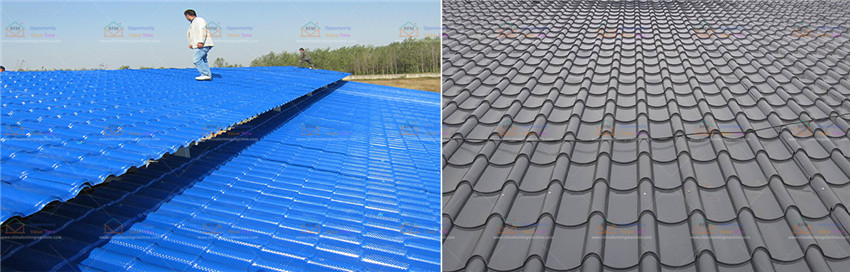

The antique glazed tile formed by the rolling die of the 828 antique glazed tile machine has the characteristics of beautiful appearance, simple and elegant, elegant and chic style, and noble taste. It can be widely used in garden-style factories, tourist scenic spots, pavilions, pavilions, hotel villas, exhibition halls, Resort and family buildings and outdoor decoration.

Before using the 828 antique glazed tile machine, it is necessary to check whether the connections are secure everywhere, whether the installation bolts and nuts are tightened, and enough lubricating oil should be added to the left and right cases before the machine can be powered on and tested.

First, carefully observe the empty car operation, whether there is vibration, noise, whether oil comes from the oil window, whether the movement of each part is coordinated, and everything can be installed before the mold is installed. When installing the mold, you must cut off the power and manually move the motor belt or large gear. The worktable is indexed and the slide is raised to a high point. An object can be supported between the worktable and the bottom surface of the slide to naturally fall with the non-slip seat, causing an accident.

The mold used by 828 antique glazed tile machine needs an upper mold and six lower molds of the same size. First install the upper mold and a lower mold. The lower mold is directly installed on the hexagonal runner table, and the upper mold is installed on the bottom surface of the slide And place the appropriate thickness of the backing plate to ensure that the gap between the four sides is uniform after the upper and lower molds are closed, and the distance between the upper and lower molds is equal to the required thickness of the tile blank.

Application Range & Scene

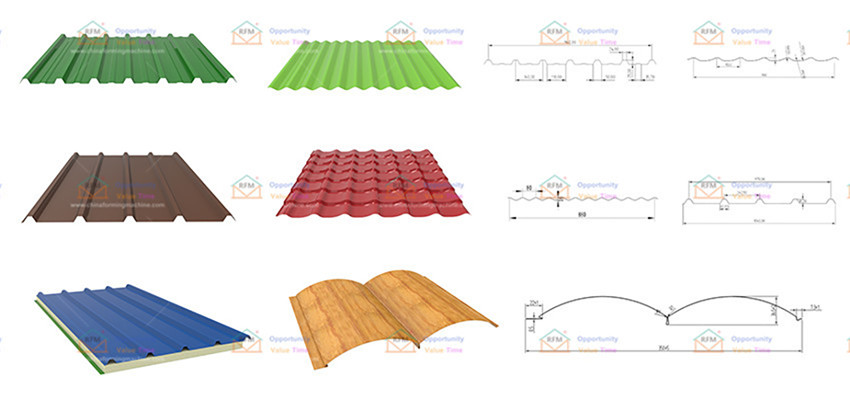

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

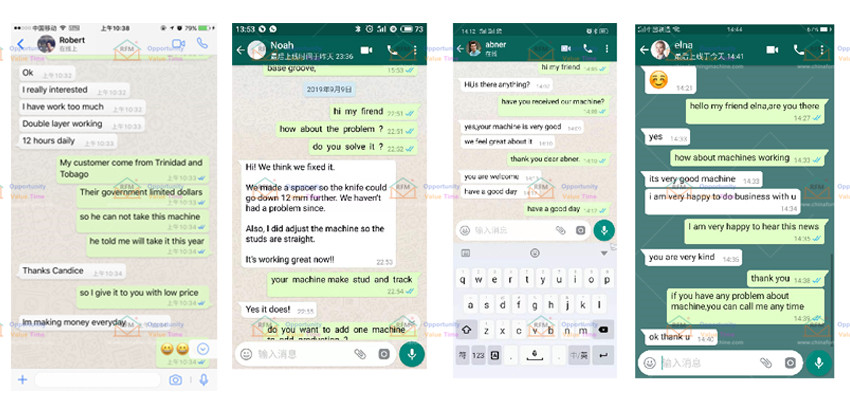

Customer Feedback