What is a Slitting Line?

I. Introduction

A. Definition of slitting line

Slitting line refers to a machine or production line used in the metalworking industry to cut or slit large coils of metal into narrower strips or sheets. The process typically involves feeding the coil through a set of rotating circular blades that cut the metal into desired widths. Slitting lines are commonly used in industries such as automotive, construction, and packaging, where narrow strips of metal are required for various applications.

B. Importance and applications of slitting lines

1. Precision cutting: Slitting lines provide precise and accurate cutting of materials, ensuring uniform strip widths and edge quality. This is crucial in industries where consistent dimensions are required, such as in the production of automotive parts, construction materials, and electrical components.

2. Increased productivity: Slitting lines enable efficient and high-speed processing of materials, leading to improved productivity. By quickly cutting large coils into smaller strips, manufacturers can meet tight production schedules and customer demands.

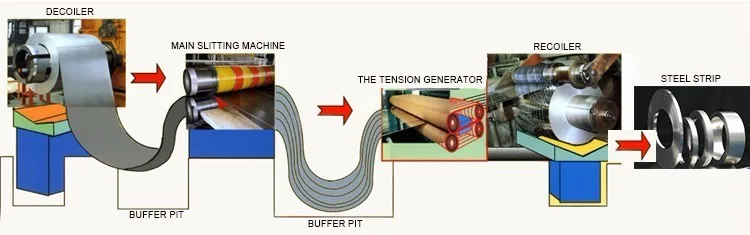

II. Components of a slitting line

A. Uncoiler

B. Slitter head

C. Recoiler

D. Scrap winder

E. Tensioning devices

F. Edge trimmer

III. Working process of a slitting line

A. Feeding the coil

B. Uncoiling

C. Slitting

D. Recoiling

E. Scrap removal

F. Edge trimming

G. Coiling

H. Packaging

IV. Advantages of using a slitting line

A. High precision and accuracy

B. Increased productivity

C. Cost-effective solution

D. Versatility in slitting different materials

E. Reduced material waste

V. Common applications of slitting lines

A. Steel industry

B. Paper industry

C. Aluminum industry

D. Plastic industry

VI. Maintenance and safety precautions for slitting lines

A. Regular maintenance schedule

B. Lubrication and cleaning

C. Safety measures for operators

D. Emergency stop procedures

VII. Conclusion

A. Recap of the importance of slitting lines

B. Future advancements and developments in slitting line technology

Learn more about products

|

Type

|

LM-450

|

LM-650

|

LM-1000

|

LM-1250

|

|

Slitting material

|

Plain carbon steel, stainless steel, copper, aluminum and alloy

|

|||

|

Slitting width

|

Max450mm

|

200~600mm

|

500~1000mm

|

600~1250mm

|

|

Material thickness

|

0.2~1.5mm

|

1.0~5.0mm

|

0.5~3.0mm

|

1.0~3.0mm

|

|

Slitting speed

|

10~90m/min

|

1.0~1.5mm ≤100m/min

|

0.5~1.0mm ≤100m/min

|

1.0~2.0mm ≤80m/min

|

|

1.5~3.0mm ≤90m/min

|

1.0~2.0mm ≤100m/min

|

2.0~3.0mm ≤60m/min

|

||

|

3.0~5.0mm ≤80m/min

|

2.0~3.0mm ≤80m/min

|

|||

|

Slitting quantity

|

≤12strips

|

≤25strips

|

≤20strips

|

≤3strips

|

|

Weight of the winder reel

|

Max2.5T

|

Max3.5T

|

Max3.0T

|

Max5.0T

|

Q1. How do I choose the right machine for myself?

1.A machine shall have complete production photographs and photographs and videos of the assembly system. 2.Pictures of engineer’s door-to-door installation. (After-sales guarantee) When selecting a plant, it is important to ensure that the company has a complete production and service system. Contact us for videos of machine production and assembly.