Coil Slitting Machine Manufacturer & Supplier

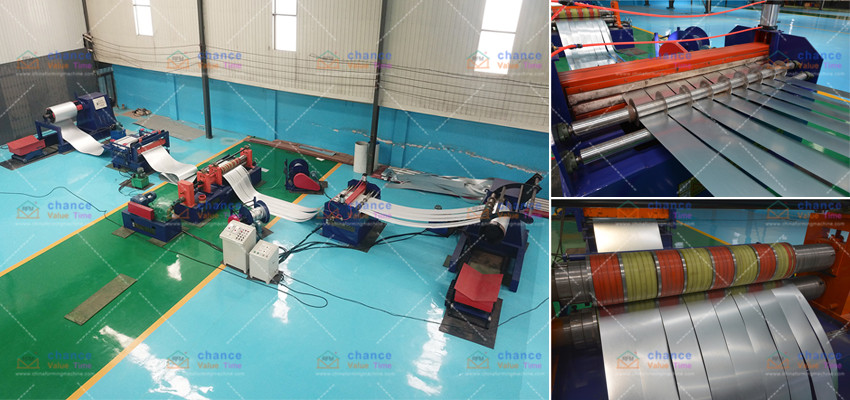

Coil Slitting Machine work process

Carry coil→ load coil →decoil→ press-guide shovel-head→ pinching→head cutting

→looping,transition→ guide→ slitting →transition→ looping & storage→

↘scrap rewinding

pre-separation, damping, press- separation →recoiling→ packing→ discharging (electric control system, hydraulic system)

CNC cut line Function :it used for flatting the coil plate, Maximum eliminate plate stress, made the stress evenly distributed.

Cut to lenth line Structure :it is composed of frame, pinch device, working roller, support roller, adjusting device of roller gap lifting incline, driven parts, etc.

· Frame, up and down crossbar and housing:plate casting steel structure, with high strength, good rigidity.

· Pinch device : a pair of pinch roller mounted on leveler entrance, to pinch the plate.

· Pinch power is through leveler distributing box by ball cage universal joints, up and down roller all have power;

· Upper roller lifting by air cylinder, gear and rack synchronous.

· Leveling device:it composed of working roller, support roller and roller stand device;

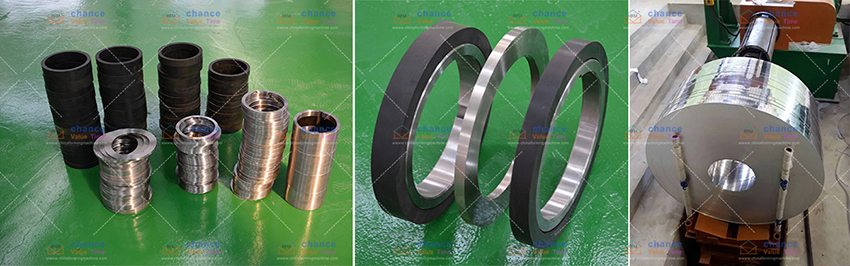

· Working roller and support rollerl are adopt rolling bearing, bearing stand is forging steel.

· Support roller :equipped with supporting roller, can manually adjust;

· Roller gap adjust device:leveler adopts adjusting device to change roller gap.

· Drive device:main motor( DC motor) through disc brake, gear speed reducer, distributing case, etc;

· Adopt ball universal joint, each working roller are have power, high efficiency and accuracy;

· Distributing case is cylindrical gear, rolling bearing, for longer life.

· Running speed is stepless adjust.

Lubrication :gear box is thin oil splash lubricate, other with think oil pump manual centralize dry oil lubricate.