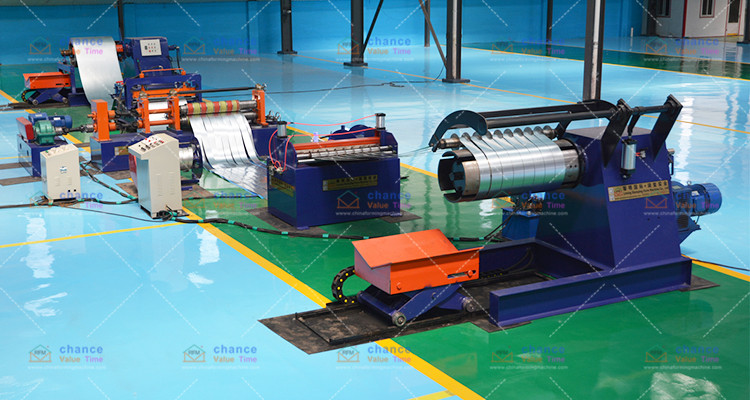

Liming Recoiler Line is ready for shipping to Brazil

The Slit-to-Recoil Line is an ideal addition to any manufacturing facility!

Liming Slit-to-Recoil Line allows the master coil to be cut down into smaller widths to be run through a trim rollformer or snap-loc machine. The machine blends the functions of our traditional slitting line with the sheet tensioner along with a coil reel and cart to rewind the steel back onto the coil.

Pneumatically adjustable

Maximum speed of up to 150 feet per minute

Up to nine knives can be purchased

29 to 22 gauge slitting capacity

Coil reel and cart have a 12,000 pound capacity to handle large coil loads

Features:

Up to 9 knives can be purchased

The slitter has the capacity to hold up to 9 knives, giving you the ability to cut up to 7 different widths for trim production.

48-inch Width Capacity

A standard size coil can be fed into the slitter to cut down to different widths. Once it is cut, it can then be recoiled back onto an empty coil cartridge to be used for making trim or snap loc.

Equipped with 4.5-inch Diameter Shafts

A standard size coil can be fed into the slitter to cut down to different widths. Once it is cut, it can then be recoiled back onto an empty coil cartridge to be used for making trim or snap loc.

Entry Table with Adjustable Guides

The 2’ entry table has adjustable guides that allow different widths of coil to be run through the machine without a taper in the material.

Do you need this recoiler line machine, just contact us!