What is a roof roofing machine?

The roofing machine is used to produce finished products as follow-type roof panels (personal roof panels refer to block roof panels) connected by perforations, nails, etc., used for house roofs, workshop roofs, industrial buildings, panel pavilions, risers, etc.

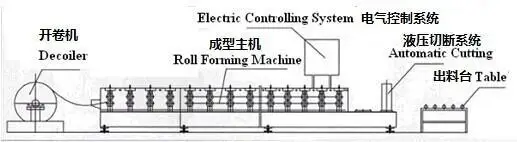

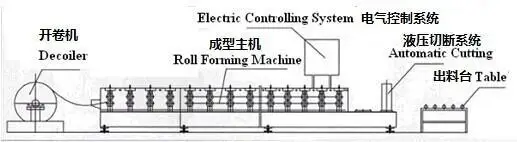

It is composed of roofing machine: uncoiling system-feeding system-forming system-shearing system-receiving system-oil pump system and electronic control system.

The roofing machine controls the shape of the product through the shape of the roller. The different needs of different countries and different countries can be customized through the specific shape provided by the customer.

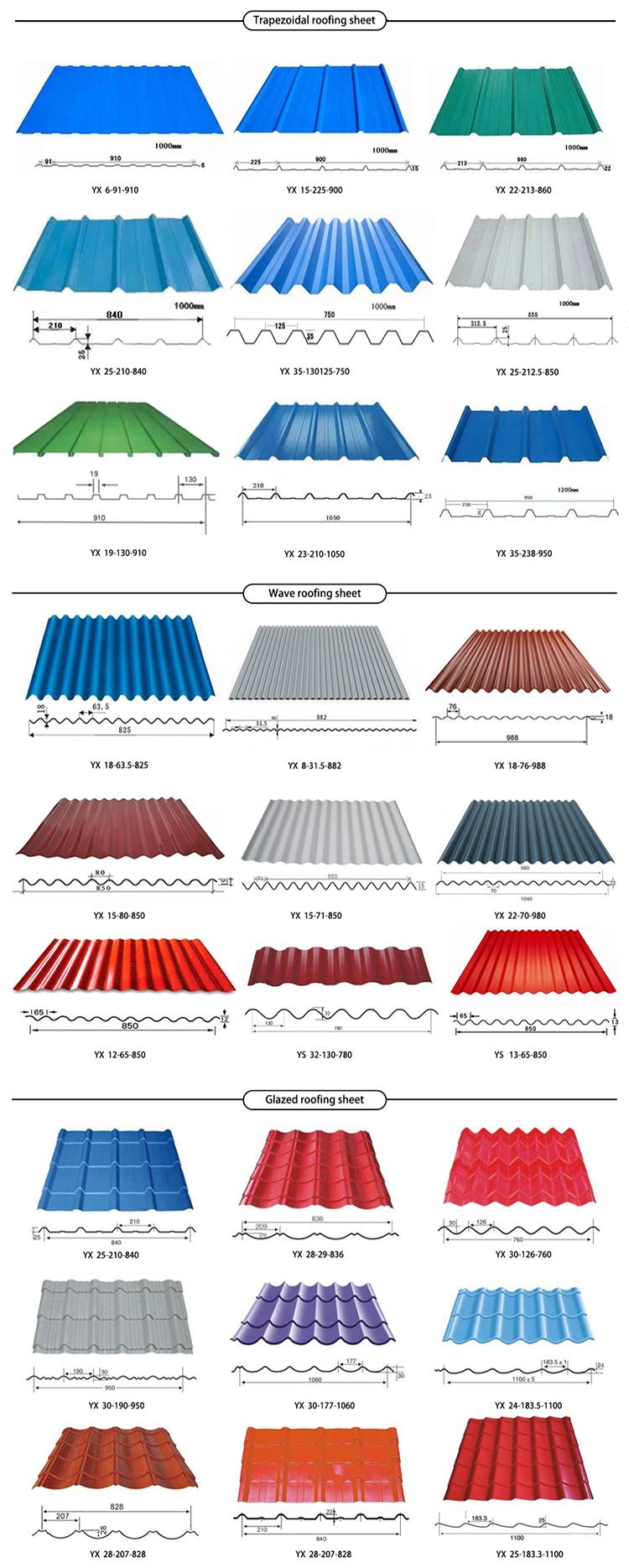

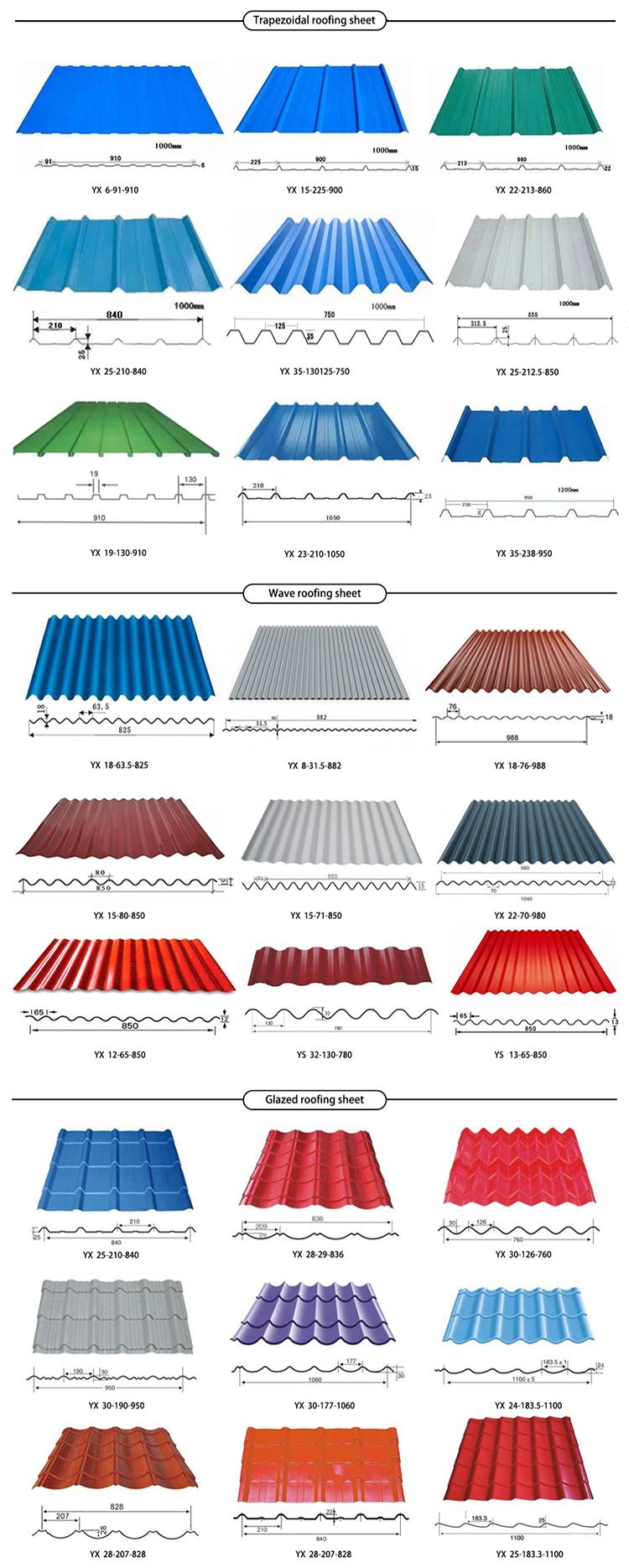

LIMING offers a wide range of galvanized roof tile machines. Likewise, these profiles are very suitable for cladding sides and large industrial and agricultural buildings. They are also used to protect privacy and increase security. Therefore, corrugated steel for wall cladding panels is the strongest profile, with a suitable custom-looking protection zone. Cladding corrugations are ideal for side cladding walls, such as barns, farms and warehouses. Of course, the following are the most common types of metal roof panels that our machines can produce. The most common types of roof panels include:

Trapezoid roof panel forming machine

Stainless steel panel roll forming machine

Corrugated roll forming machine

Glazed tile forming machine

IBR roof panel forming machine

Trapezoidal roofing machine machine

Color-coated trapezoidal panels are used by construction industries all over the world because of their corrosion resistance, beauty and durability. Therefore, trapezoidal roof tiles are widely used in steel structure buildings, steel structure projects and enclosure systems. Installing trapezoidal profiles provides you with a simple and powerful way to cover roofs and walls. In fact, LIMING can produce various high-quality Trapezoidal roof sheet machine with different sheet thickness, cross-sectional area and moment of inertia according to your requirements.

ibr roofing machine

At the same time, IBR roof panels are designed to be used as side cladding or roofing materials for commercial, industrial and residential buildings. The name IBR is short for “Inverted BoxRib” and has become a household name in the South African construction industry. Of course, IBR roof panels are available in a variety of colors and materials, showing various structural characteristics. The IBR roof is an alternative to zinc roof tiles and is quick and easy to install. It can be made of a variety of metals, including steel and aluminum, and is easier to install.

There are two different types of IBR board profiles, IBR 686 profiles and IBR 890 profiles. Roofing cladding panels or side cladding panels are widely used in South Africa. However, in South Africa, the standard 686IBR sheet profile is a more popular machine than other metal roof sheet roll forming machines.

In addition, LIMING also designs and produces various types of roof forming machines. We have changed the traditional oil pump system to make the production environment cleaner. The high-speed roof slab forming machine we manufacture; the machine cooperates with the motion control electric shearing system, and the speed can reach 50m/min. We can design the roofing machine according to your extrusion and shape.

How to make roofing panels?

In short, the roof tiles are formed by rolling by a roofing panel manufacturing machine for the production and use of house metal roof tiles, IBR panels, market color-coated roof panels, etc.,

so you can contact the LIMING roofing panel forming machine with more than 25 years of experience Manufacturer, we produce more than 300 different cross-section roofing machine. Therefore

LIMING produces general-speed and high-speed metal roof forming machines according to customers’ regions and applications. In addition, the metal roof forming machine requires more than 600 preferred rollers and approximately 30-60 shafts. Choose a metal roof panel manufacturer. We must first check whether the supplier is a production plant, production capacity and mechanical capabilities, and roll forming production experience, in order to produce high-quality roof panel machines.