Metal roofing machine experts in China

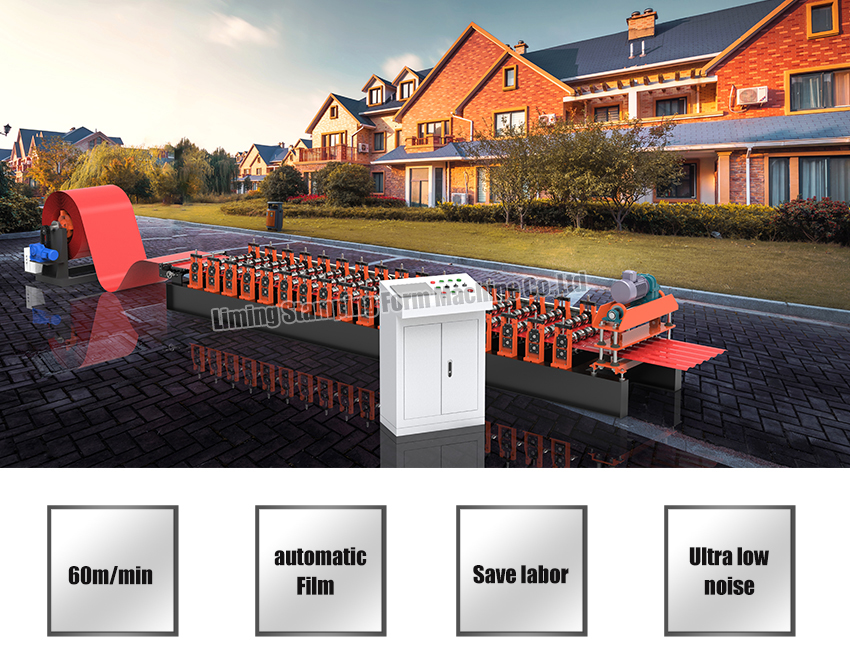

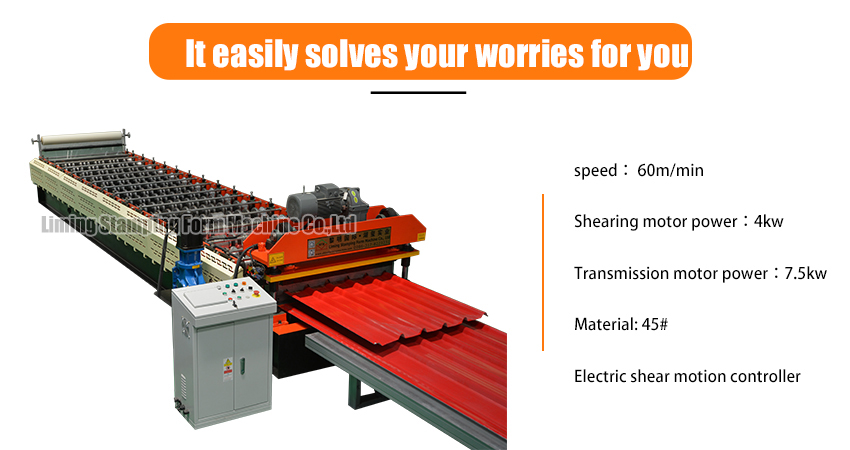

The industry’s highest speed 60 m/min metal roofing machine

The industry’s highest speed 60 m/min metal roofing machine

The speed of this metal roofing machine can reach 60 meters per minute, which is 3 to 5 times that of ordinary roofing machines, which meets the requirements of large roof profile wholesalers for machine output.

The machine abandons the mobile oil pump of the original design and adopts an integrated hydraulic system, which will not cause the hydraulic oil to cause the floor of the workshop to be messy. The electronic control system uses Delta motion controller and Siemens motor to cut, so the speed can reach 60m/ min.

We will make a metal roofing machine installation file for each exported machine, which many factories cannot provide. The file details the various parts of the machine and the installation method, which can not only help him realize the rapid installation of the roofing machine, but also Increase the market competitiveness of the machine when reselling.

If you feel that the manual cannot help them install and use the machine, you can still contact us at any time. We will use video teaching or send engineers to the site to guide the installation method until their factory can fully grasp the installation and use of the roof forming machine.

Every year, our designers go to first-class machinery factories in Finland, Germany, and France to learn advanced manufacturing technology and services from European factories; to improve themselves and help customers with minimal project investment; to obtain the quality and service of European machinery

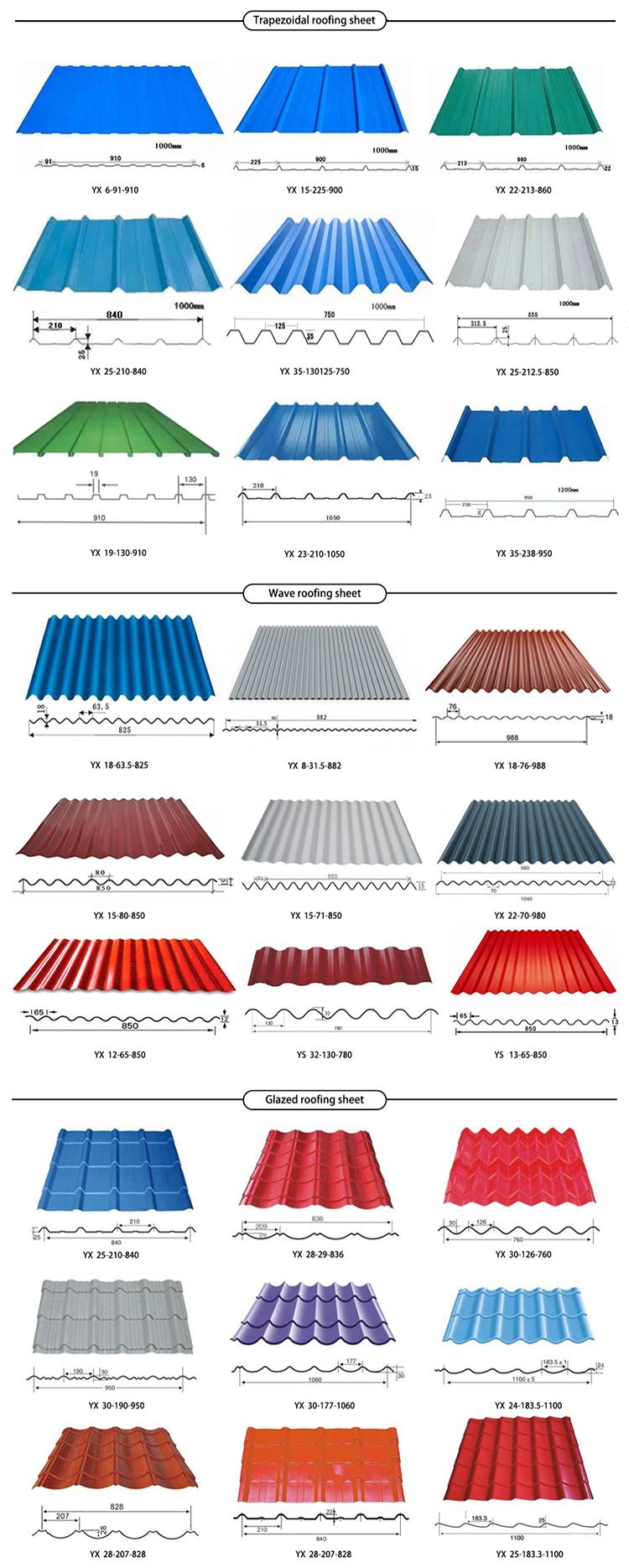

— Select products, customize machines —

The product shape can be divided into ladder type, arc type, and glazed tile according to its purpose; You can choose the metal roofing machine to be produced based on the locally popular products.

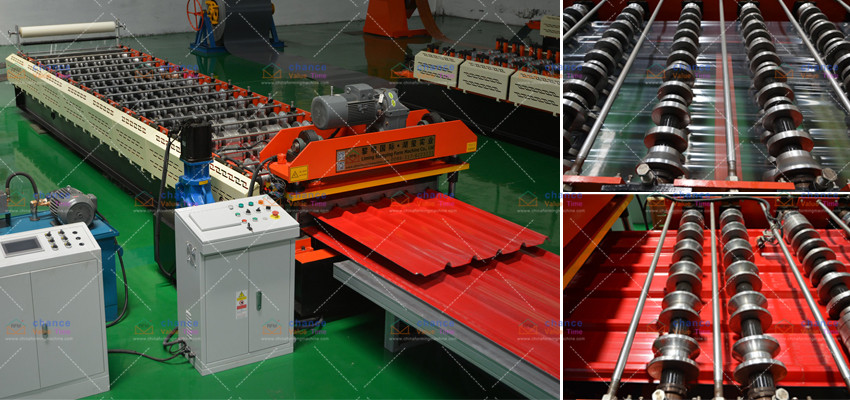

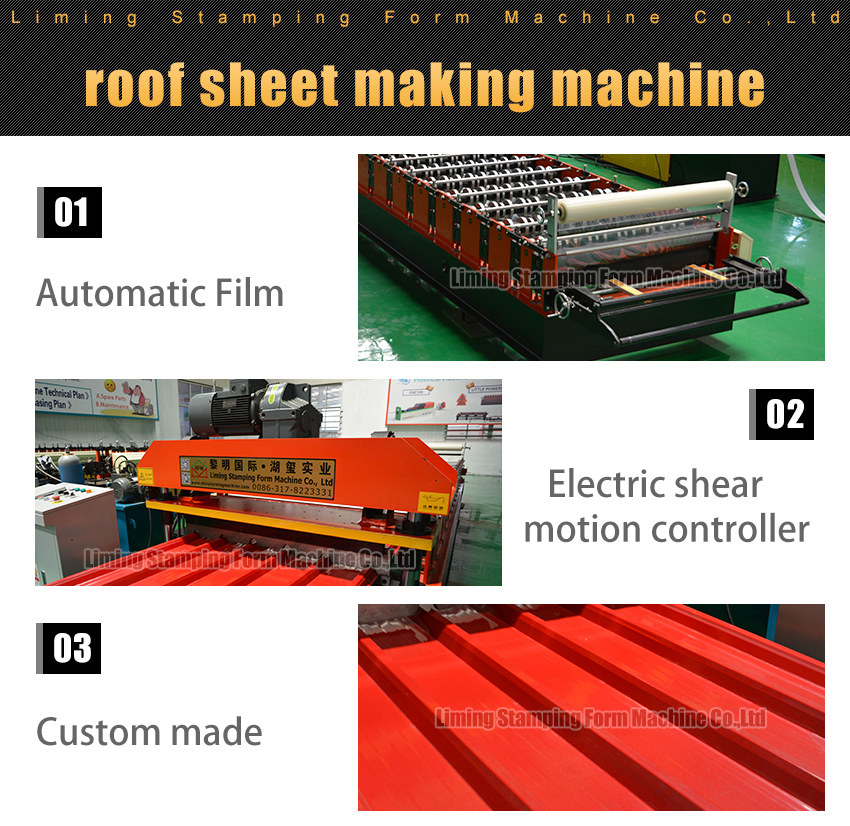

metal roofing machine detail

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.