What does a roll forming machine do?

What does a roll forming machine do?

Rolling forming machine, roll forming is a type of roller, which involves continuous bending of long metal plates (typically coiled steel) into the required cross section.

The strip steel passes through several groups of rolls installed on the continuous frame, and each group of rolls only performs the incremental part of bending until the required cross section (profile) is obtained.

Rolling forming is an ideal choice for the production of long length and large quantities of equal section parts.

The roll forming machine can produce molded products in various industries

including: metal roof tiles, ceiling profiles, dry wall profiles, roller shutter door curtains, metal door frames, photovoltaic support frames, light-weight frame house profiles C89/C140, shelf columns, shelf beams, supermarket shelf laminates, floor support plate profiles, studs and tracks.

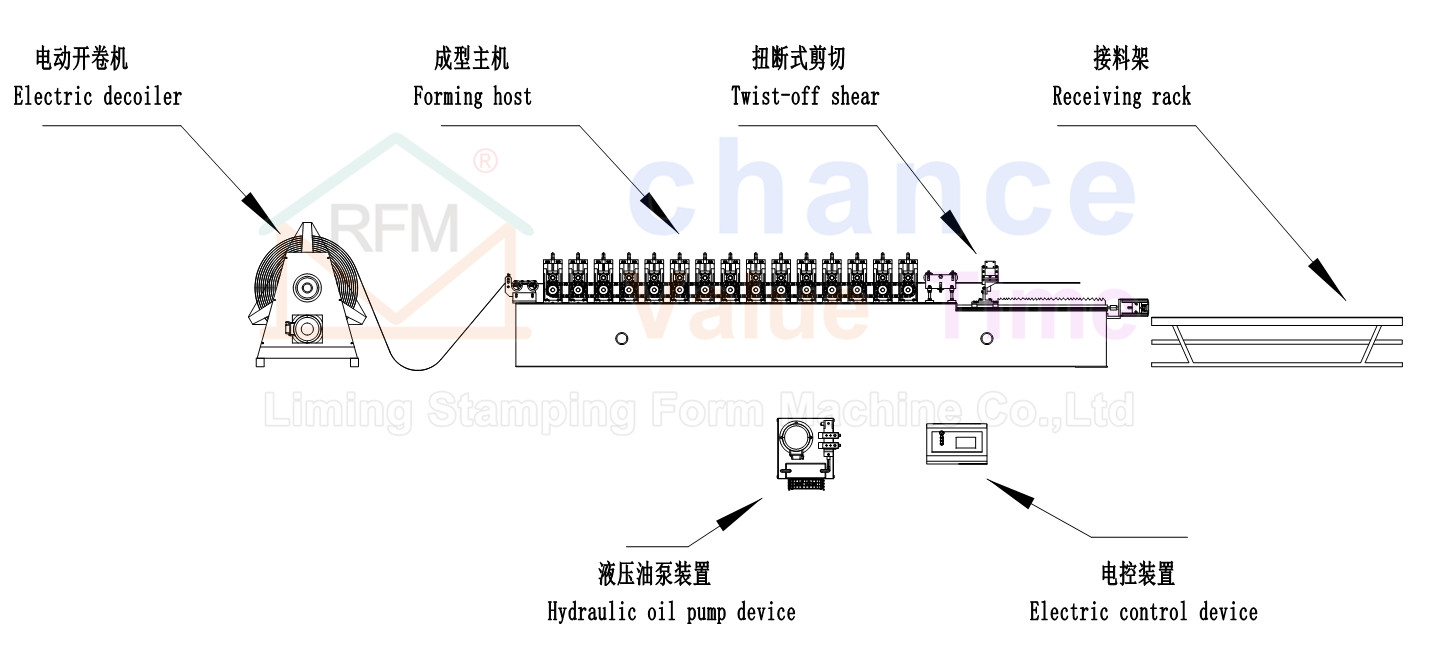

The roll forming parts are composed of uncoiler – feeding rack – forming host – cutting system – hydraulic system – electric control system.

The product shape is controlled by the roller shape, so each roll forming machine can only produce one shape, but the bottom size can be adjusted.

Liming Stamping Form Machine Co.,Ltd is a solution provider of roll forming machine integrating customer demand design and production and manufacturing of roll forming machine

It has served more than 20000 customers in more than 79 countries around the world. It has solved the problems of entrepreneurship, market development, market research and popular products for customers, and helped them to open many factories. This is also the purpose of our company

Our company has been established for 26 years, which can guarantee the strength of many customers and help them when they need us most. Many trading companies,

small companies that have been established for several years, have reasons or cannot go abroad to provide after-sales service for you when you need them

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.