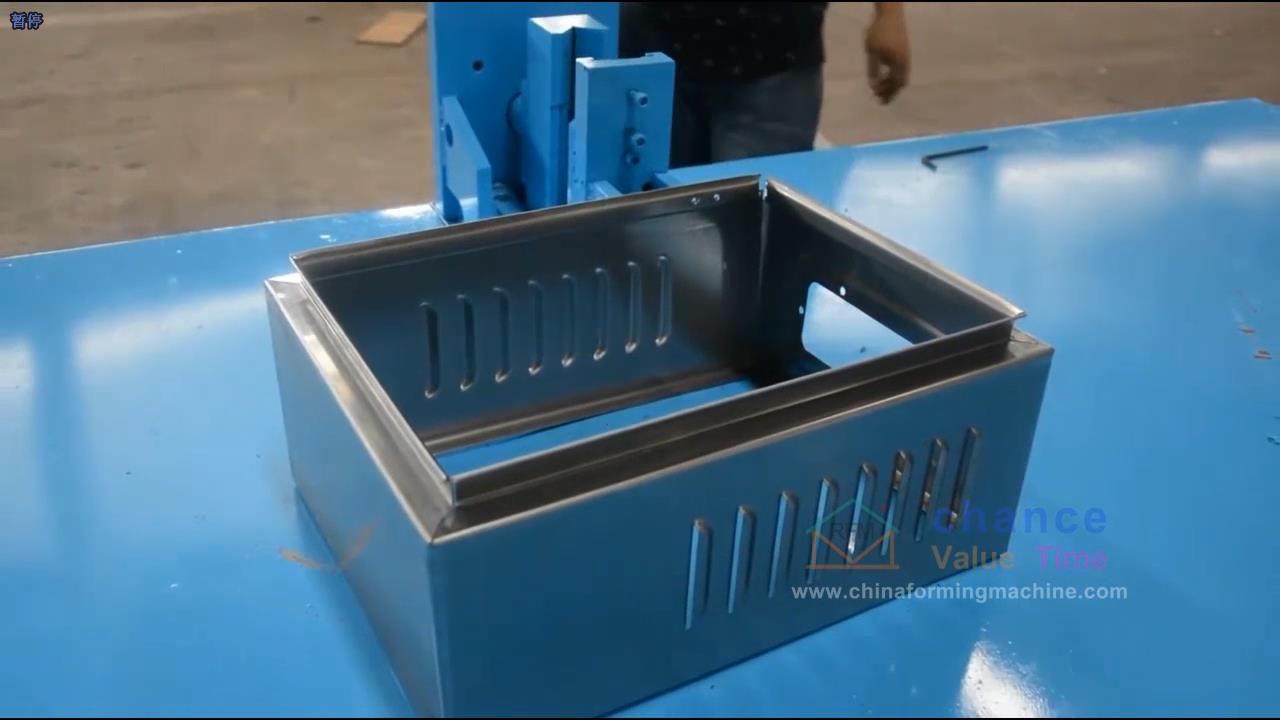

automatic one-piece forming machine

The automatic one-piece forming machine for the outer frame of the distribution box covers an area of about 50 square meters. It is composed of precision cold-formed main machine, cut-to-length device, automatic frame folding device, electrical control system and other components;

Main functions: automatic corner removal, servo automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

Advantages of the automatic production line of the automatic integrated forming machine for the outer frame of the distribution box:

1. Highly automated procedures to reduce manual operations;

2. High work efficiency, increase enterprise production capacity;

3. The production process of the whole process is stable, and the quality and consistency of the products are improved;

4. Mass production reduces the production cost of the enterprise.

The process flow of the automatic all-in-one forming machine for the outer frame of the distribution box:

Strip steel feeding → steel coil unwinding → material leveling → high-precision servo feeding → multi-station combined servo punching → high-precision cold bending forming → cutting → folding frame → receiving → electrical control system