Double Light Keel Roll Forming Machine

Our

factory is a leading manufacturer for steel plate coiling machinery

roll-forming and automatic production

lines. The product are mainly used on steel structure industry for producing

C&Z shape purlin , load-bearing

plate of building wall and

roof protestive structure colorful steel plate and so on we own

the good after-sales service

network ,and can provide support covering the whole process of purchasing, help

you get the prefect machinery , make sure

that we will solve all problem when you use the machine

conveniently and immediately ,we will provide you considerate .

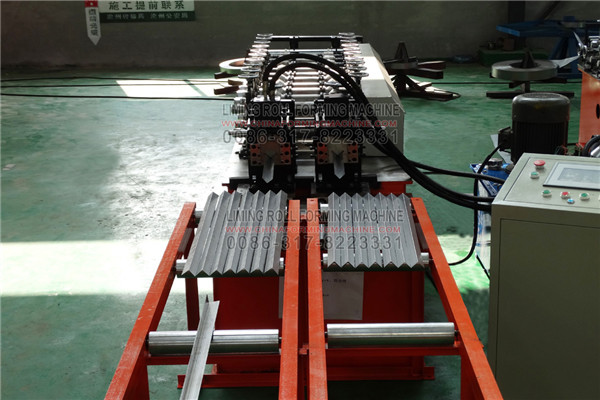

Double

Light Keel Roll Forming Machine consists of feeding,

forming, after molding, products smooth appearance beautiful appearances,

uniform lacquer veins, high strength, durable, widely used in industrial and

civil buildings, such as workshop, warehouse, locomotive shed, hangar room,

gymnasium, exhibition halls, theaters and other surface and wall.Its components include:

machine, PLC computer control system, hydraulic pump station system, automatic

after shearing system equipment.OMEGA KEEL ROLL FORMING MACHINE components

include: machine, PLC computer control system, hydraulic pump station system,

automatic cutting system .

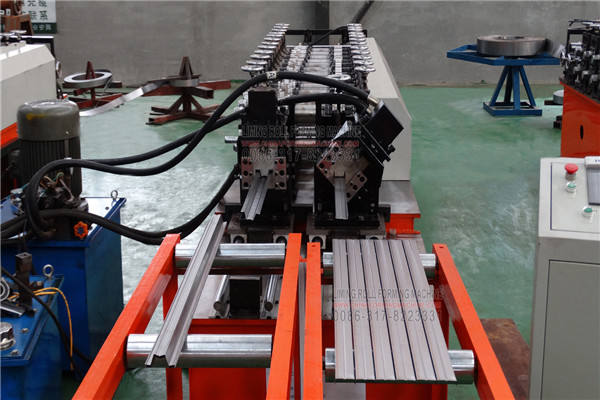

Double Light Keel Roll Forming Machine features: This device uses

a high level of color steel automatic control software, production information

management. The entire unit automation control system uses a highly integrated

network, automation systems and better performance. Corrugated steel sheet Roll

forming machine also has maintenance, mechanical maintenance and debugging

advantages of easy mold replacement.

Double Light Keel Roll

Forming Machine cutter

portion is driven by a hydraulic cylinder to move up and down the tool, you can

put steel cut off. Corrugated steel

sheet Roll forming machine production process is as follows: steel roller into

the molded part after molding to-pressure part, pressed into an equidistant

one, the cutter is responsible for cutting to length. Double

Light Keel Roll Forming Machine control

information on the implementation part of a frequency converter drive motor,

hydraulic motor, two-pressure hydraulic solenoid valves, two hydraulic cutter

solenoid valves.

Whatsapp

: +86 18031705152

Email

:liming3@chinaformingmachine.com

Phone

number is 15716892380