roof flashings roll forming machine suppliers

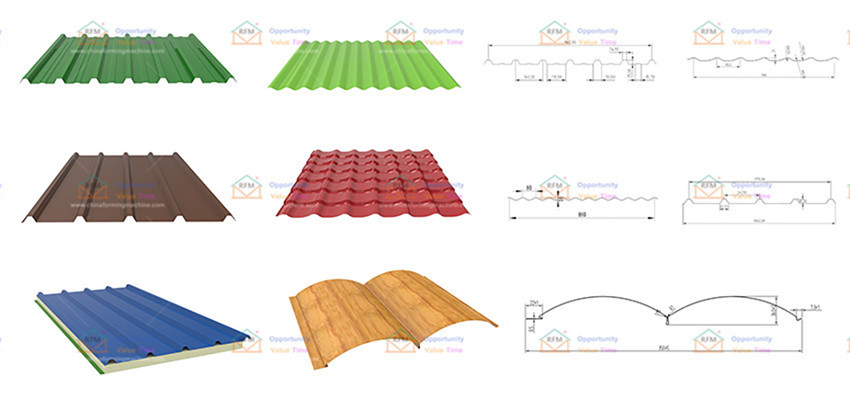

roof flashings roll forming machine can produce sandwich composite panels with a thickness of 40-300mm and a width of 1000-1200mm; corrugated high-strength composite panels with a thickness of 50-100mm and a width of 950mm. Forming is composed of unwinding, forming and post-forming cutting. The products produced are smooth and beautiful in appearance, uniform in paint texture, high in strength and durable. They are widely used in industrial civil buildings such as workshops, warehouses, hangars, hangars, gymnasiums, Rooms and walls such as exhibition halls and theaters. Its components include: complete machine, PLC computer control system, hydraulic pump station system, and fully automatic post-shear system. The tile press equipment includes: complete machine, PLC computer control system, C-shaped steel machine system, and fully automatic post-shear system.

roof flashings roll forming machine structure and material: cold-formed steel is the main material for making light steel structure, which is made of cold-formed steel plate or steel belt. The wall thickness of the C-shaped steel machine can be made very thin, and the production process is greatly simplified and the production efficiency is improved. It can produce all kinds of profiles with different wall thicknesses and complex cross-section shapes that are difficult to produce by the general hot rolling method and cold-formed colored steel equipment with different materials. However, due to the complicated structure, high cost, many parts, and time-consuming assembly of the multi-link suspension, and to achieve the durability of the non-independent suspension, it is always necessary to keep the connecting rod from deforming or shifting. It is very elegant and structurally optimized, so the multi-link suspension is based on the pursuit of excellent handling and driving comfort.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

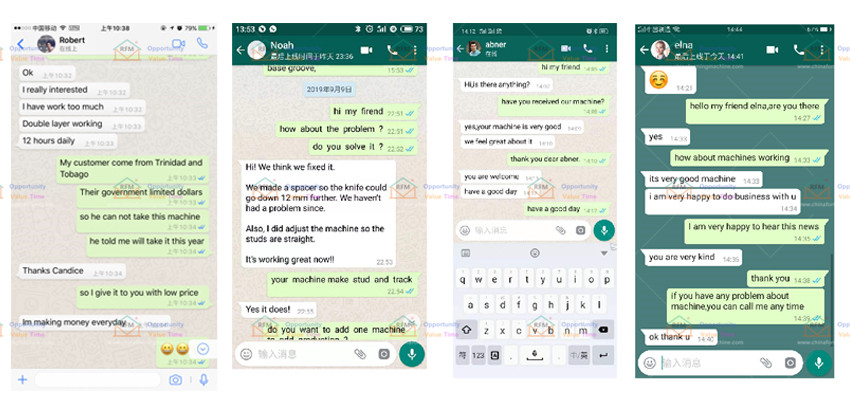

Customer Feedback