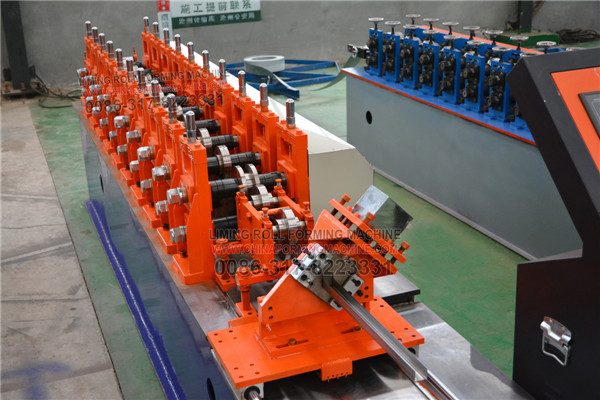

U Profile Roll Forming Machine

Cold-formed

production line program description

First,

the device specific parameters:

Product

Material Material: A3

Product

material thickness: 0.4mm-1.5mm

Product

molding speed: 0-12m / min

Total

equipment power: about 12 KW

Equipment

Power: AC 380V, 50Hz, three-phase

Control

power: AC 220V, 50Hz, single phase

Line

direction: for the console, from (left) to (right) direction.

Second,

the product molding process:

3T putter

– hydraulic punching – rolling forming host — Straighten — cut off —

cutting length

Third,

the equipment structure:

(1) part

of the rack

Electric

discharge rack configuration: 1 Taiwan

Can be

placed outside diameter material size: ≤ 1300mm

Hole

diameter contraction: Ф350mm ~ Ф510mm

Can be

put material width: 300mm

Can be

put material weight: 1000Kg

Zoom

Type: Manual

With

manual brake

(2) the

host part

Basic

structure of the project

The

overall structure of the rack 100X100X4mm square tube welding

Floor

16mm

Side

plate 25mm

Feed type

guide plate guide

Forming

rolling material GGr15 wear-resistant bearing steel

Zharan

processing: quenching, hardness HRC58-60 ℃, hard chrome plated surface treatment

Spindle

Φ52mm

Spindle

bearings (each side of the board) are used on the shaft 6009, the lower shaft

are used 6210 ball bearings each one

Host

power 5.5kw motor

Main

drive system: The drive is driven by the motor through the 250 gearbox sprocket

connected with the linkage gear to drive the gear wheel to rotate synchronously

Straightening

system 2 sets of straightening machine

Fourth,

the operating environment:

1: Power

supply voltage: 380V ± 10% / three-phase four-wire, frequency: 50HZ.

2:

Ambient temperature: 0-40 ℃, relative humidity: 60-95% RH.

Quality

Assurance: The supplier guarantees that the materials and components used are

made of the best materials and components, and the main electrical components

are original, new and unused, and fully comply with the contract quantity,

specifications, Performance and requirements of the demand side, the supplier

of the production line rolling die warranty for two years, the other components

a year (since the date of acceptance).

Pls

contact with me if you want it.

Liming

Stamping Form Machine Co.,Ltd

Address:No

3 Road, Industrial Development Zone, Botou City,Hebei Province, China